4-20 mA Vibration Monitoring

Download the printer-friendly 4-20 mA Vibration Monitoring application note

Overview

4-20 mA technology can be used to measure temperature, pressure, flow, and speed as well as the overall vibration of rotating machines. Adding a vibration sensor/transmitter to the machine provides a critical measure of the machine’s health, and can be used to identify changes in balance, alignment, gears, bearings, and many other potential faults.

How It Works

The purpose of the 4-20 mA analog current loop is to transmit the signal from an analog vibration sensor over a distance in the form of a 4-20 mA current signal. The current signal generated is proportional to the overall vibration of the equipment or machinery that is being monitored. This output current has a range of 4-20 mA, with 4 representing the minimum and 20 representing maximum amplitudes (within the range of 4-20 mA). The 4-20 mA signal output is proportional to the defined amplitude generated within a specified frequency band. Therefore, the signal does not include data from frequencies outside the frequency band but includes all vibration (critical and non-critical faults) within that band.

What We Offer

CTC offers a wide array of 4-20 mA output solutions for industrial applications. CTC’s standard 4-20 mA loop powered vibration sensors are available with velocity or acceleration, alongside temperature output measurement options. CTC’s loop-powered sensor line also includes a dual output option, with both 4-20 mA output and dynamic output configurations in one sensor. Other options include 24 Volt DC-powered transmitters that power standard IEPE accelerometers and convert the vibration to a powered 4-20mA signal. These transmitters also offer a 4-20 mA output for temperature when coupled with CTC dual output vibration and temperature sensors.

LP200 and LP300 Series

A loop power vibration sensor/transmitter like the LP200 Series (4-20 mA proportional to vibration measured in velocity) or the LP300 Series (4-20mA proportional to vibration measured in acceleration) can be mounted on the machine and added to the control loop. As the overall vibration of the machine changes, the 4-20 mA output will vary proportionally.

LP202 Loop Power Sensor, 4-20 mA Output Proportional to Vibration in Velocity, Top Exit 2 Pin Connector

LP204 Loop Power Sensor, 4-20 mA Output Proportional to Vibration in Velocity, Side Exit 2 Pin Connector

LP302 Loop Power Sensor, 4-20 mA Output Proportional to Vibration in Acceleration, Top Exit 2 Pin Connector

LP304 Loop Power Sensor, 4-20 mA Output Proportional to Vibration in Acceleration, Side Exit 2 Pin Connector

Only two wires are required to supply power to the sensor and send the current signal. A loop supply voltage is used to power the remote sensor. A series resistor RL at the loop power supply converts this current to a voltage that can be used by the process monitor/controller to record or distribute the parameter being measured.

LP200 and LP300 Data Flow

Dual Output LP23X and LP33X Series

Dual output LP26X and LP36X Series sensors contain an integrated circuit to measure the temperature inside the sensor case. The temperature output is monitored in the form of mVDC/°C using a voltmeter across pins C & B of the sensor when the circuit is powered by the 4-20mA loop at pins A & B. The DC voltage output is proportional to temperature from -40 °C (0.10 VDC) to +100 °C (1.35 VDC) or -40 °F (.10 VDC) to +212 °F (1.35 VDC). This output can be trended in voltage to monitor the change in temperature of the machine.

Hazardous Rated Sensors

CTC offers the Intrinsically Safe LP800 and LP900 series of sensors for hazardous locations.

Available LP800 and LP900 Series ratings:

ATEX Zone 0,1

ATEX Zone 2

CSA Class 1, Division 1

CSA Class 1, Division 2

IECEx Zone 0,1

Signal Conditioner / Field Configurable

Signal conditioners can be used in conjunction with standard dynamic accelerometers, piezo velocity sensors, or displacement probes. The Signal Conditioner accepts the dynamic input and converts it to a proportional 4-20 mA output for the PLCS, DCS or SCADA system.

SC320 Series Signal Conditioner, USB Configurable, Dual Band Vibration / Ultrasound Plus Temperature Output

The Signal Conditioner can be adjusted in the field so that the scaling and filters match your application. The dynamic vibration signal is available from a standard BNC connection on the front of the Signal Conditioner, or as an optional output from the terminal block.

The signal conditioner is also compatible with the TA202, TA204, TA231, TA233, and TA284 series dual output vibration and temperature sensors. The signal conditioner in combination with any of these sensors will provide one 4-20 mA output proportional to vibration, and a second 4-20 mA output proportional to temperature.

Additional 4-20 mA Products

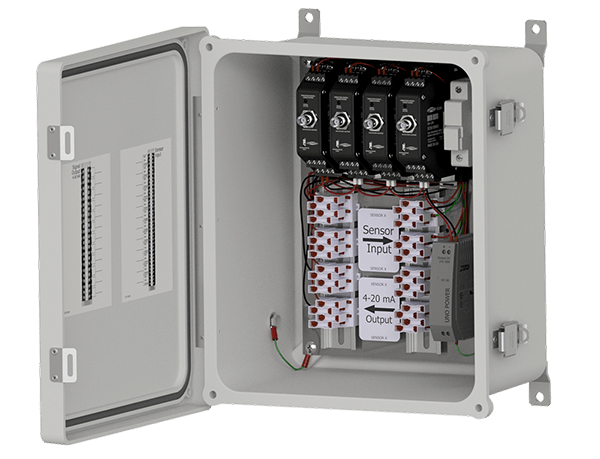

SCE Series Signal Conditioner Enclosures:

- Provides 4-20 mA signals along with dynamic outputs from remotely installed accelerometers to PLC / DCS systems and portable data collectors

- Accommodates 1-8 CTC SC Series signal conditioners factory wired to DC power supply (100 - 240 VAC)

- Available in fiberglass and stainless steel options

- 15 to 140 °F (-10 to 60 °C) temperature range

- NEMA 4X (IP66) rated

- Fiberglass Relay and Display Enclosure for 1 to 4 single output loop power sensors

- Sunlight viewable display of vibration levels: IPS, g's, mils, or customized scale

- Relay includes two Form C relays per process controller

- Optional red or tri-color stack light with optional horn alarm

- Relays trigger alarm or shutdown*

*shutdown feature only available when used without the optional stack light - 32 to 140 °F (0 to 60 °C) temperature range

- NEMA 4X (IP65) rated

- Relay and Display Enclosure for 1 to 4 CTC Signal Conditioners

- Sunlight viewable display of vibration levels: IPS, g's, mils, or customized scale

- Relay includes two Form C relays per process controller

- Optional red or tri-color stack light with optional horn alarm

- Relays trigger alarm or shutdown*

*shutdown feature only available when used without the optional stack light - 32 to 140 °F (0 to 60 °C) temperature range

- NEMA 4X (IP65) rated