Proximity Probe Mounting Options

Download the printer-friendly Proximity Probe Mounting Options Overview

Monitoring of journal bearings (also known as sleeve bearings or plain bearings) is generally accomplished by using “eddy current” or proximity probes.

proximity probes are often used to monitor turbine shafts in power plants

These probes use the fluctuations induced in an electromagnetic field generated by the probe to determine the bearing shaft position relative to the bearing casing and the dynamic vibration of the rotating shaft. Proper probe mounting will have a significant effect on the validity of the data measured by the monitoring system.

In general, two probes mounted 90 degrees apart are the most commonly used configuration for mounting radial proximity probes. Each probe monitors the position of the shaft relative to the ‘X’ or ‘Y’ location. DP1001 series probes are recommended for most applications.

pictured above - DP1001 8mm PRO Proximity Probe

There are three primary methods of mounting the probes: (1) internally mounted, (2) through mount (internal / external) where the probes are mounted through the bearing casing and the casing is counter bored to prevent the probe from side sensing, and (3) externally mounted on the outside of the machine and measure an exposed portion of the shaft.

1. Internal Mounting

By mounting the eddy current probes completely inside the machine or bearing housing with PRO DM902 series brackets, or with custom designed and manufactured brackets, three things are accomplished:

- The probe measures the shaft surface.

- The costs of installation are minimized.

- The measurement of the shaft position and vibration is precise.

pictured above - DM902-1A Mounting Bracket - aluminum proximity probe mount, clamping version, for 3/8-24 probe bodies

Advantages / Disadvantages of Internal Mounting

The probes must be installed and properly spaced before the bearing cover is reinstalled. An accommodation must be made for the probe cable to exit the bearing housing. This can be accomplished by using an existing plug or fitting, or by drilling and tapping a hole above the oil line and properly sealing to avoid leaks. The cables must also be tied down inside the bearing housing to prevent cable damage or failure from contact with the shaft.

On the down side, there is no access to the probe at all when the machine is running. All fasteners inside the bearing housing should be safety wired or otherwise prevented from loosening inside the machine. Extra care must be taken at the cable exits to prevent leakage.

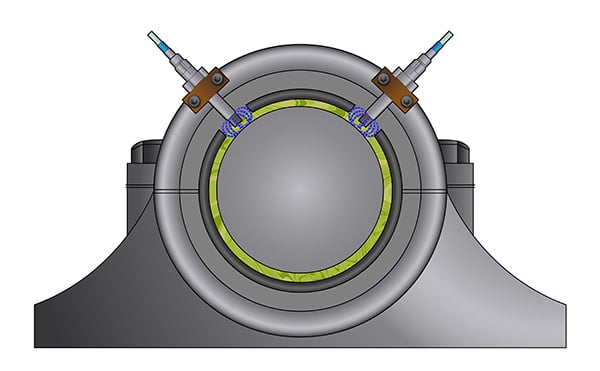

2. Through Mounting

Through mounting, which is also referred to as ‘internal / external,’ is where the probe is mounted through the bearing casing and the casing is counter bored to prevent the probe from side sensing or providing false readings from the bearing housing.

pictured above - diagram depicting through mounting

pictured above - close up detail of through mounting

Internal / external mounting is accomplished when an appropriately sized hole is drilled and tapped directly through the bearing housing, or the proximity probes are mounted with a Mounting Adapter Bushing like the PRO DM901 and DM903 series. These adapters allow external access to the probe while also allowing the probe tip to be internal to the machine or bearing housing.

pictured above - DM901-1A - 1/2-14 NPT bushing with 3/8-24 threaded hole

pictured above - DM903-1A - 3/4-14 NPT to 3/4-14 NPSM bushing with 3/8-24 threaded hole

Advantages / Disadvantages of Through Mounting

Care must be taken in drilling and tapping the bearing housing or cover to ensure that the probes will be perpendicular to the shaft center line. The benefits of this standard mounting include the ability to replace or adjust the probes without disassembly of the bearing, and the location typically offers a good viewing area of the probe.

3. External Mounting

External proximity probe mounting is typically used when other methods are not available. Special care must be given to the quality of the shaft surface, and mechanical protection of the exposed probes and cables is required.

pictured above - diagram depicting external mounting

Advantages / Disadvantages of External Mounting

Exposed areas of the shaft may experience scuffing, scratching or rust which limits the measurement quality of the probes. If the shaft is inspected and found to be clean and smooth, then this location may be used for measurement. The advantages of this mounting style are the low cost and the easy access to the probes.