Success Story: ASCRIBO + CTC Connect Prevent Bearing Failure in Belt-Driven Fan System

A special thank you to our approved software integrator ASCRIBO for this success story

Click here to download the printer-friendly pdf version of Success Story: ASCRIBO + CTC Connect Prevent Bearing Failure in Belt-Driven Fan System

Introduction

At a white paper production facility, ASCRIBO was tasked with monitoring a belt-driven fan system. The fan system utilized 1311 EKTN9 self-aligning ball bearings with tapered bores. Belt-driven fan systems are a critical part of air handling and process ventilation in paper mills. These fans are typically used to:

- Regulate airflow in drying sections

- Remove moisture and heat from production areas

- Maintain environmental control for sensitive paper processing operations

Because they operate continuously and often under variable load conditions, these systems are subject to mechanical stress and wear, especially in the bearings, pulleys, belts, and fan rotors.

Location / Application

Paper Mill / Belt-Driven Fan System

Technology Used

ASCRIBO ABLE System + CTC ConnectSensTM Wireless Sensors and ConnectBridgeTM Wireless Gateway:

Analysis

To proactively monitor the fan system, the facility deployed the ASCRIBO ABLE System, integrated with CTC ConnectSensTM wireless triaxial MEMs sensors and ConnectBridgeTM wireless gateway. These sensors collected vibration data every 60 minutes, which was autonomously analyzed using ASCRIBO's advanced unsupervised learning algorithm.

The bearing housing on the pulley side of the vacuum fan from which vibration data was collected in three axes at 60-minute intervals.

Findings

This approach eliminated the need for manual signal interpretation and enabled real-time fault detection across key components:

- Motor and fan support bearings

- Pulleys

- Fan blades

- Shaft assemblies

It was determined that the fan system was experiencing static imbalance in the fan rotor as a result of persistent angular loads, leading to degradation of the pulley-side bearing over time.

The ABLE System identified fault frequencies associated with:

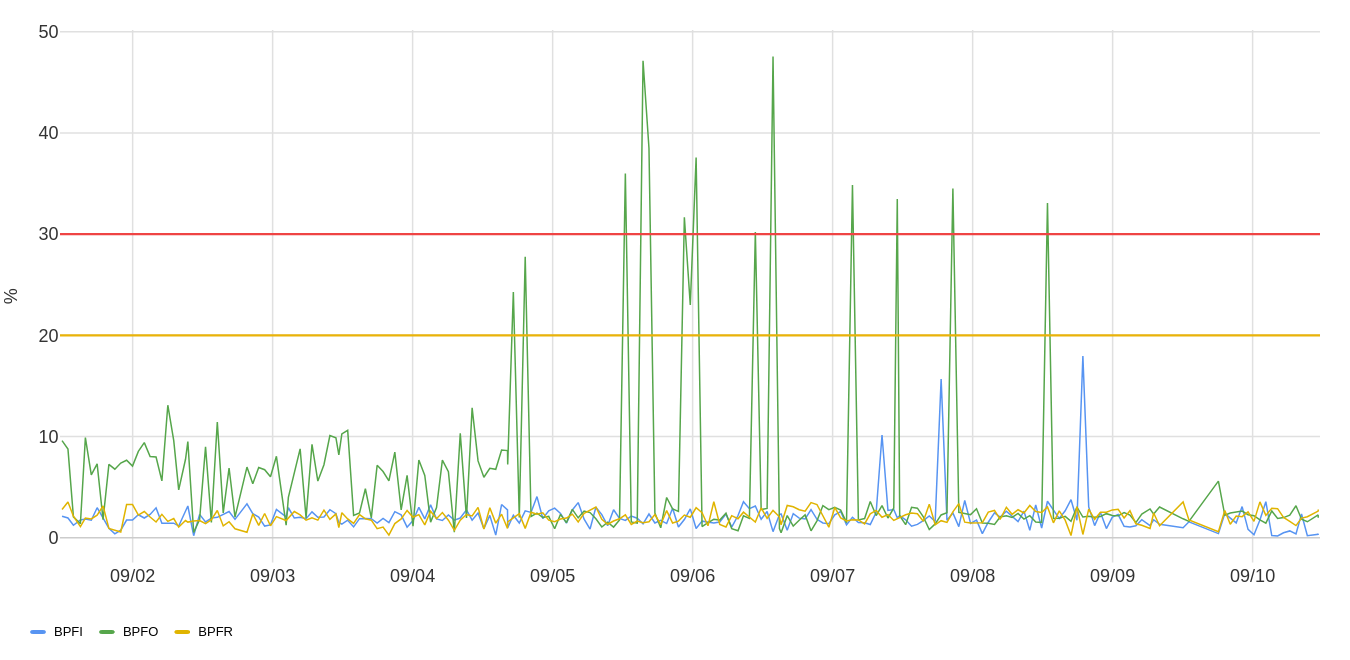

Outer Raceway (BPFO) shows that an advanced-level fault developed on the outer raceway and could be detected independently of varying speed and load

Outer race fault trend, vertical axis

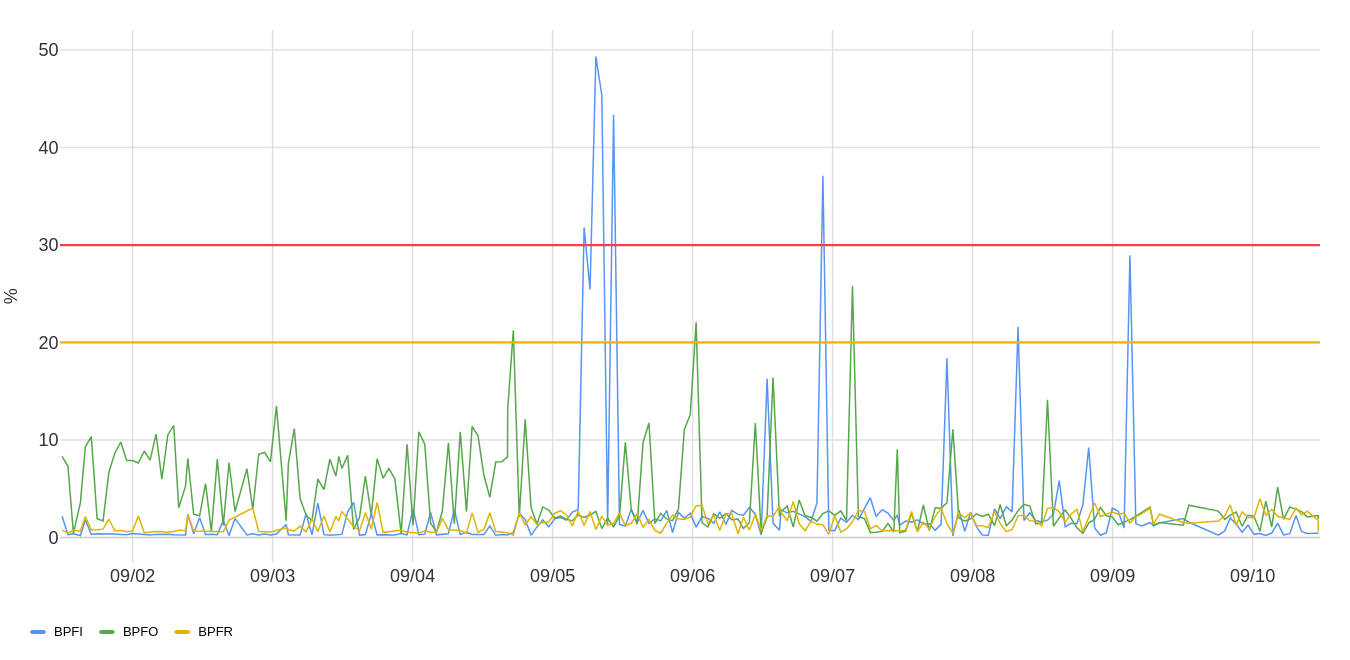

Inner Raceway (BPFI) reveals that an advanced-level fault developed on the inner raceway. Notably, this fault was detected independently of varying speed and load.

Inner raceway fault trend, horizontal axis

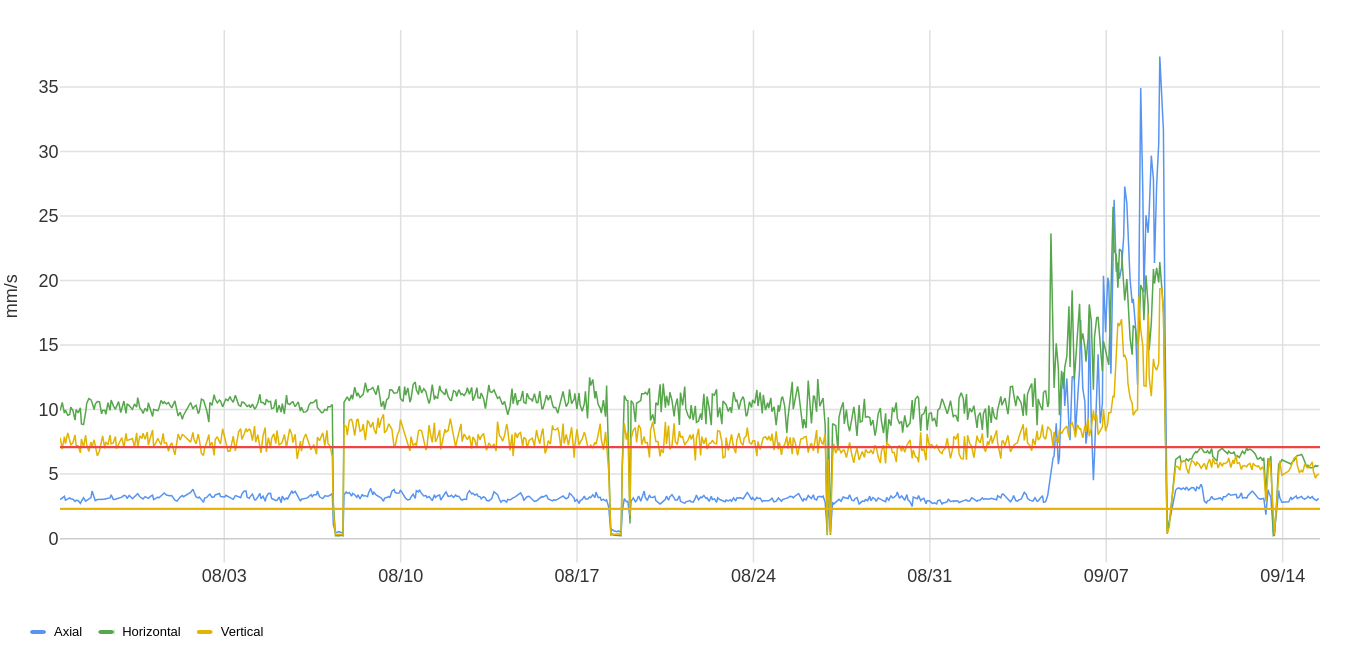

While the overall vibration levels at the fan's pulley-side bearing housing were fluctuating around 15-20 mm/s, a systematic increase was observed on all three axes after a specific date, rising to levels of 30-35 mm/s.

3-axial RMS Velocity (mm/s)

These findings were later confirmed during maintenance:

- Scratches, pits, and distributed defects were found on the outer raceway

- A localized fault was observed on the inner raceway

Outcome

The fan system was taken offline during a planned shutdown, and the diagnosis was confirmed. The support bearings and fan rotor were replaced and post-maintenance vibration levels dropped below danger thresholds across all axes.

This success story demonstrates how ASCRIBO's ABLE System, powered by CTC Connect, delivers:

- Autonomous fault detection

- Early warning of mechanical degradation

- Reduced unplanned downtime

- Lower maintenance costs

___________________________________

Interested in ASCRIBO + CTC Connect? Learn more