The Cartesian Coordinate System Explained

Download the printer-friendly Cartesian Coordinate System Overview

There is a good chance that you already know what the Cartesian coordinate system is, at least in concept, but simply did not know the term. It is a way to map points in 3-dimensional space by assigning values to each direction. Think of it like a map. If you were walking around New York City from Central Park to the Empire State Building, you would have to travel a certain distance west and a certain distance south. With these two values, you can figure out how far it is between the two locations. But what if you wanted to know how far it is from Central Park to the top of the Empire State building? You would need to have another direction to describe how tall the building is. This is where the Cartesian coordinate system comes in.

In the Cartesian coordinate system, moving horizontally left and right is considered moving along the X-axis. Similarly, moving up and down is the Y-axis. You can use these two points to see how far along a point is on a graph like the one shown below. The green point on the graph is 12 units in the X direction and 5 units in the Y direction.

(notebook image courtesy of upklyak / Freepik)

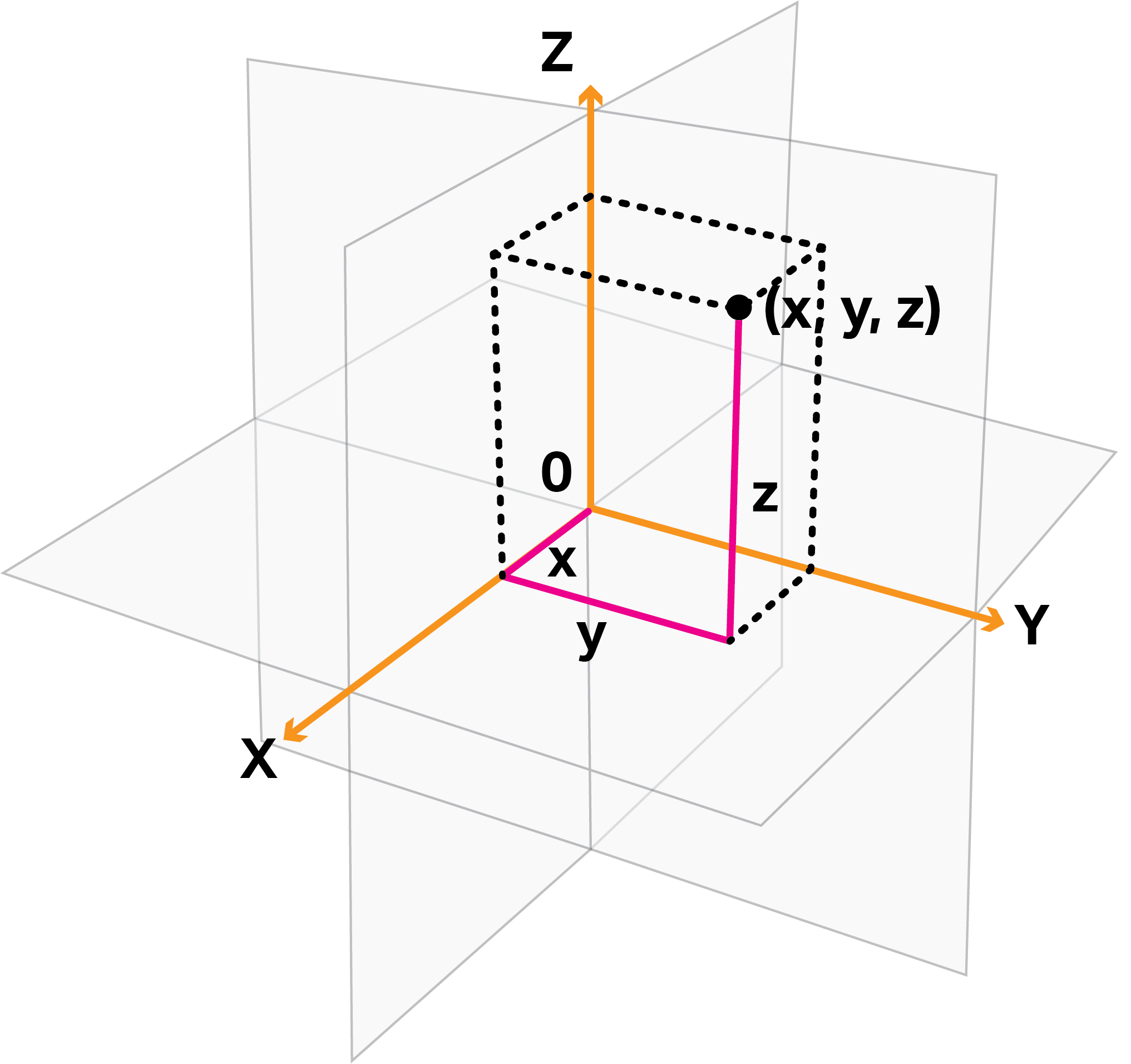

X and Y axes can be used to describe a point in two dimensions, but it could never be used to illustrate more than just a flat surface. You need a third axis, called the Z-axis, to describe the depth of an object. If X-axis is left and right and Y-axis is up and down, then the Z-axis is in and out. The following graph is what it would look like when you add the Z-axis in:

How Does This Relate to Vibration?

Everything in our physical world exists and moves in these three dimensions. Therefore, everything in our world vibrates in these three directions. With a single-axis sensor, the only measurement taken is the Z-axis.

This is helpful in many cases since this is in line with the vibration coming from the machine you mounted the sensor to which in most cases would be the largest source of vibration. If you have a piece of equipment that could vibrate in multiple directions, you would need a sensor that can measure them all simultaneously. Enter the triaxial sensor.

The wide variety of CTC triaxial sensors, such as the TREA330 below, have been designed with the Cartesian coordinate system in mind. Relating to how the sensor is marked, you can see that the three axes follow the same principle that the X-axis is left to right, the Y-axis is up and down, and the Z-axis is in and out relating to the surface on which it is mounted. The circle around the Z engraved on the sensor itself is used to describe an in-and-out motion that cannot be visualized on the two-dimensional surface of the sensor body.

TREA330 - Premium Miniature Triaxial Accelerometer, 100 mV/g, ±5%

- Frequency Response (±3dB): 30-900,000 CPM

- Dynamic Range: ±80g, peak

- Voltage Source: 18-30 VDC

- Temperature Range: -65 to 250 °F (-54 to 121 °C)

- Case Material: 316L Stainless Steel

- Connector: 4 Pin Mini-MIL