Ultrasound & Eddy Current Monitoring for Sleeve Bearing Health

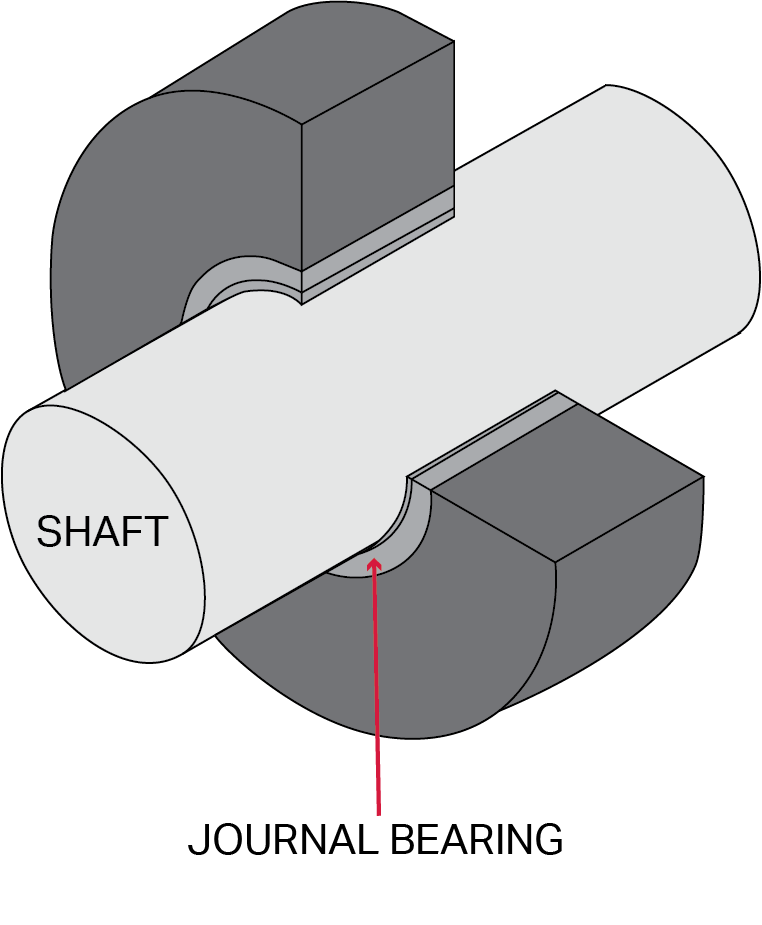

Combining ultrasound analysis with eddy current monitoring for sleeve bearings, also known as fluid film or journal bearings, can offer a comprehensive approach to monitor displacement and assess lubrication levels.

Here's how this integrated approach can be applied specifically to sleeve bearings:

Ultrasound Analysis for Lubrication Monitoring

Ultrasound sensors placed near the sleeve bearings can detect changes in the ultrasonic signals associated with friction and wear. Adequate lubrication typically results in stable ultrasound patterns, while deviations may indicate issues such as insufficient lubrication or lubricant degradation.

UEB332 dynamic vibration IEPE ultrasound sensor, miniature size, top exit, 100 mV/g, ±10% sensitivity tolerance

UEA332 dynamic vibration IEPE ultrasound sensor, miniature size, side exit, 100 mV/g, ±10% sensitivity tolerance

Eddy Current Monitoring for Displacement Analysis

Eddy current sensors, also known as proximity probes, placed strategically on the sleeve bearings can monitor the displacement of the bearing surfaces. Changes in displacement patterns can be indicative of wear, misalignment, or other mechanical issues affecting the sleeve bearings.

8 mm proximity probe set featuring probe, extension cable, and driver

Correlation of Ultrasound and Eddy Current Data

Correlation ultrasound data with eddy current displacement data allows for a more comprehensive understanding of the relationship between lubrication conditions and mechanical behavior. For example, an increase in displacement detected by eddy current monitoring may be associated with changes in ultrasound patterns indicating altered friction due to lubrication issues.

Early Detection of Lubrication and Mechanical Issues

The integrated approach facilitates early detection of both lubrication and mechanical issues. Changes in ultrasound and displacement data can collectively signal potential problems, allowing for proactive maintenance to address lubrication deficiencies or mechanical abnormalities before they escalate.

Identification of Specific Lubrication Problems

Different lubrication issues, such as inadequate lubrication, contamination, or changes in lubricant viscosity, may have distinct effects on ultrasound and displacement patterns. The combined monitoring approach enables the identification of specific lubrication problems contributing to bearing health issues.

Condition-Based Maintenance Strategies

The integrated approach supports condition-based maintenance strategies for sleeve bearings. Rather than adhering to fixed schedules, maintenance interventions can be planned based on real-time data indicating changes in displacement, lubrication conditions, or other factors influencing sleeve bearing health.