Vibration Monitoring for the Mining Industry

Download the printer-friendly Vibration Monitoring for the Mining Industry Application Note

Equipment used in the mining industry is subject to heavy use, dirty environments, and often high temperatures. These factors can result in increased wear and tear on rotating components, creating the threat of premature failure.

Condition monitoring programs can be used to monitor the vibration of the bearings throughout the plant and improve the reliability of the overall process.

Other important equipment to be monitored within the mining industry includes:

- Crushers

- Mills

- Conveyors

- Precipitators

- Kilns

- Silos

Common faults which can be detected include:

- Unbalance

- Misalignment

- Blade Pass

- Vane Pass

There are several challenges to monitoring mining equipment, including:

- Safety concerns

- Limited accessibility

- What needs to be continuously monitored?

- The impacts of corrosion, dust, and debris

The first consideration is whether or not process monitoring or dynamic vibration analysis is right for your condition monitoring program.

Process monitoring requires 4-20 mA loop power sensors, which provide the overall vibration level of the machine so that it can be trended and alarmed using the plant DCS, PLC, or SCADA system. Process monitoring requires permanently mounted loop power sensors like LP200 and LP300 Series that output a 4-20 mA signal proportional to velocity or acceleration. Process monitoring will provide an overall understanding of machine health, but cannot provide the same level of detailed, diagnostic data as dynamic vibration analysis.

Loop Power Sensor Offerings for Process Monitoring:

LP202 Loop Power Sensor

4-20 mA Output Proportional to Vibration in Velocity, Top Exit 2 Pin Connector

LP204 Loop Power Sensor

4-20 mA Output Proportional to Vibration in Velocity, Side Exit 2 Pin Connector

LP302 Loop Power Sensor

4-20 mA Output Proportional to Vibration in Acceleration, Top Exit 2 Pin Connector

LP304 Loop Power Sensor

4-20 mA Output Proportional to Vibration in Acceleration, Side Exit 2 Pin Connector

Dynamic Vibration Analysis allows for trended data and machine health diagnostics. However, Dynamic Vibration Sensors can be paired with CTC’s SC300 Series Signal Conditioners to create a hybrid approach for both Process Monitoring and Dynamic Vibration Analysis.

SC320 Series Signal Conditioner

USB Configurable, Dual Band Vibration/Ultrasound Plus Temperature

A signal conditioner converts the signal from a dynamic sensor into a 4-20 mA output, so it can be trended and alarmed using the plant DCS, PLC, or SCADA system but also used for more in-depth predictive maintenance. Regardless of whether or not a signal conditioner is the right choice for your program, CTC has a variety of accelerometers for use in mining applications.

In general, CTC multipurpose 100 mV/g sensors can be used for the majority of mining applications.

Standard Accelerometer Offerings (for environments up to 250 °F):

AC102 Multipurpose Accelerometer

Top Exit 2 Pin Connector, 100 mV/g, ±10%

AC104 Multipurpose Accelerometer

Side Exit 2 Pin Connector, 100 mV/g, ±10%

AC292 Premium Compact Accelerometer

Top Exit 2 Pin Connector, 100 mV/g, ±5%

AC294 Premium Compact Accelerometer

Side Exit 2 Pin Connector, 100 mV/g, ±5%

UEB332 Dynamic Vibration IEPE Ultrasound Sensor

1/4-28 Mounting, Top Exit 2 Pin Mini-MIL Connector, 100 mV/g, ±10%

UEA332 Dynamic Vibration IEPE Ultrasound Sensor

1/4-28 Mounting, Side Exit 2 Pin Mini-MIL Connector, 100 mV/g, ±10%

For applications where temperature monitoring is necessary, CTC also offers a variety of Dual Output Vibration and Temperature Sensors.

Dual Output Vibration and Temperature Sensor Offerings:

TA202 IEPE Dual Output Sensor

Temperature & Acceleration, Top Exit 3 Pin Connector, 100 mV/g, 10 mV/°C, ±10%

TA204 IEPE Dual Output Sensor

Temperature & Acceleration, Side Exit 3 Pin Connector, 100 mV/g, 10 mV/°C, ±10%

TR102-M12A RTD Dual Output Sensor

Top Exit 4 Pin M12 Connector, 100 mV/g, ±10%

TR104-M12A RTD Dual Output Sensor

Side Exit 4 Pin M12 Connector, 100 mV/g, ±10%

VT202 Dual Output Piezo Velocity Sensor

Velocity & Temperature Output, Top Exit 3 Pin Connector, 100 mV/in/sec, 10 mV/°C, ±10%

VT204 Dual Output Piezo Velocity Sensor

Velocity & Temperature Output, Side Exit 3 Pin Connector, 100 mV/in/sec, 10 mV/°C, ±10%

For high-temperature environments, CTC also has a variety of high temperature resistance sensors that can operate up to 350 °F.

High Temperature IEPE Offerings (for environments up to 350 °F):

AC207 High Temperature IEPE Accelerometer

325 °F (162 °C) Max Temp, Top Exit 2 Pin Connector, 100 mV/g, ±10%

AC208 High Temperature IEPE Accelerometer

325 °F (162 °C) Max Temp, Side Exit 2 Pin Connector, 100 mV/g, ±10%

TXEA331-HT High Temperature Triaxial Accelerometer

Premium 100 mV/g, Side Exit 4 Pin Connector, ±5%

J4R Triaxial Accelerometer Compatible Connector

4 Socket Mini-MIL Connector for CTC 4 Pin Triaxial Accelerometers, PPS Molded, Permanent Mount, 392 °F (200 °C) Max Temp

CB206 Armor Protected Cabling

Low Cost, Twisted, Shielded Pair Cable, Lightweight Red FEP Jacket with Stainless Steel Outer Armor, 0.27 in. (6.9 mm) OD, 392 °F (200 °C) Max Temp

CB218 Armor Protected Cabling

4 Conductor Shielded Cable, Red FEP Jacket with Stainless Steel Outer Armor, 0.27" (6.9 mm) OD, 392 °F (200 °C) Max Temp

For low-frequency applications (12 CPM to 30 CPM [0.2 Hz to 0.5 Hz]) like gearboxes, often used in fans and conveyors, 500 mV/g sensors should be used.

Low Frequency Application Offerings:

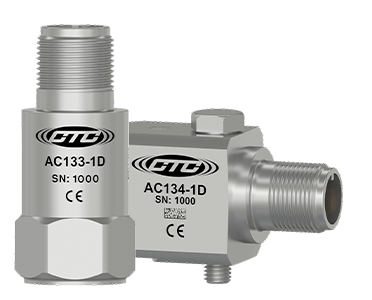

AC133 Low Frequency Accelerometer

Top Exit 2 Pin Connector, 500 mV/g, ±10%

2 Socket MIL-Style, Seal-Tight Viton™ Boot Connector with Nylon Insert, Permanent Mount, 250 °F (121 °C) Max Temp

V3R Biaxial and Dual Output Compatible Connector

High Temperature 3 Socket MIL-Style Seal-Tight Viton™ Boot Connector with PPS Insert, Permanent Mount, 350 °F (177 °C) Max Temp

A2R Standard Accelerometer Compatible Connector

High Temperature 2 Socket MIL-Style, PPS Molded Connector, Permanent Mount, 392 °F (200 °C) Max Temp

A3R Biaxial and Dual Output Compatible Connector

High Temperature 3 Socket MIL-Style, PPS Molded Connector, Permanent Mount, 392 °F (200 °C) Max Temp

3 Socket MIL-Style, Right Angle, Nylon Molded Connector, Permanent Mount, 250 °F (121 °C) Max Temp

Since many mining applications have hazardous environments due to gas, oil, or dust that could create a combustible atmosphere in around machines, CTC offers hazardous-rated sensors by certifying organizations including: ANZEx, ATEX, CSA, IECEx, and KC

CB296 Armor Protected Cabling

Class 1, Division 2 Approved, Twisted, Shielded Pair Cable, Lightweight Red FEP Jacket with Stainless Steel Outer Armor, 0.27” (6.9 mm) OD, 392 °F (200 °C) Max Temp

MH118 Series Motor Fin Mount Pads

Available in a variety of widths and heights to fit your specific application

CB206 Standard Armor Jacketed Cable

Low Cost, Twisted, Shielded Pair Cable, Lightweight Red FEP Jacket with Stainless Steel Outer Armor, 0.27 in. (6.9 mm) OD, 392 °F (200 °C) Max Temp

CB618 Heavy Duty Armor Jacketed Cable

4 Conductor, ShieldedCable, Red FEP Jacket with Heavy Duty Stainless Steel Outer Armor, 0.303 in. (7.7 mm) OD, 392 °F (200 °C) Max Temp

CB802 Stainless Steel Braided Sheathing

Twisted, Shielded Pair Cable, Red FEP Jacket with Stainless Steel Braided Outer Sheathing, 0.25 in. (6.4 mm) OD, 392 °F (200 °C) Max Temp

CB502 Hydraulic Hose Jacketed Cabling

Twisted, Shielded Pair Cable, Red FEP Jacket with Hydraulic Hose Outer Armor, 0.5 in. (12.7 mm) OD, 212 °F (100 °C) Max Temp

Sloped-Top Junction Boxes

CTC's Sloped-Top Junction Boxes are specifically designed for mining applications. Due to the presence of dust and debris in mines, the pitched roof of our sloped-top boxes prohibits particles from settling on the box.

Sloped-Top Junction Box Offerings:

SSB6000 Modular Sloped-Top Box

Single Axis, Sloped Top, Modular Vibration Switch Box, Stainless Steel Enclosure, NEMA 4X (IP66) Rated, Includes SSB-MOD(X) for 1 to 12 Single Output Sensor Inputs

SB262 Sloped-Top Switch Box

Single Axis Sloped Top Vibration Switch Box, Stainless Steel Enclosure, NEMA 4X (IP66) Rated, Sensor Input Options: 4 to 12 Single Output Sensor Inputs

JB310 Sloped-Top Junction Box

IBox Single-Axis, Sloped-Top Vibration Switch Box, Stainless Steel Enclosure, NEMA 4x (IP66) Rated, Sensor Input Options: 4 to 12 Single-Output Sensors