Vibration Sensor Mounting Techniques

Frequency Response / Mounting Techniques

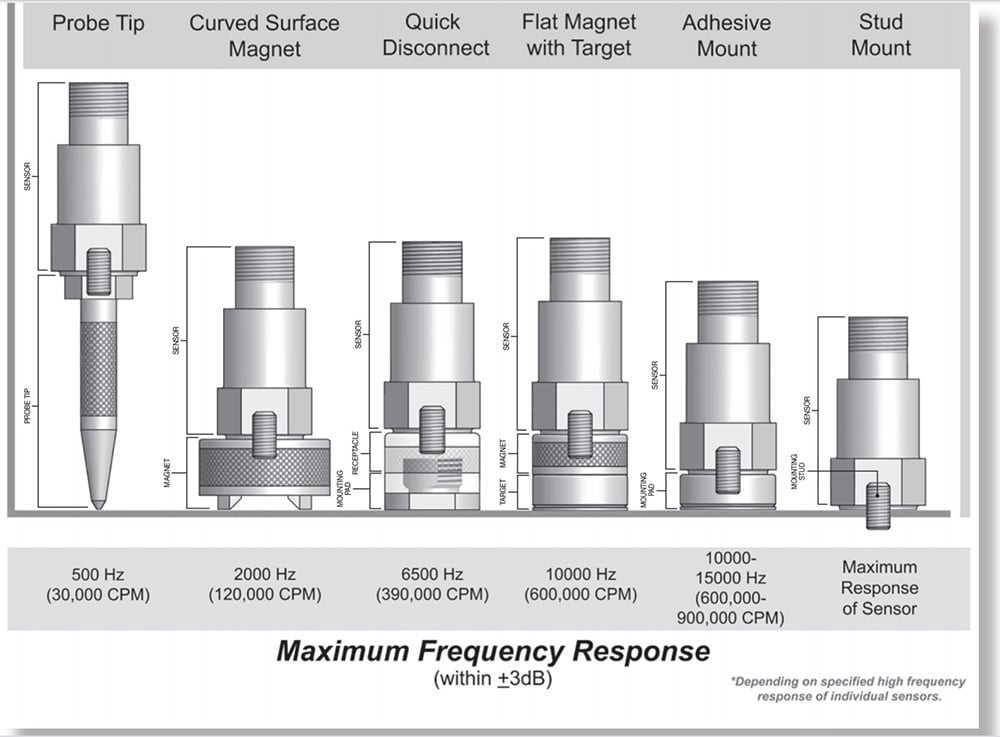

The accuracy of your high-frequency response is directly affected by the mounting technique that you select for the sensor.

In general, the greater the mounted surface area contact between the sensor and the machine surface, the more accurate your high-frequency response will be. High-frequency response is based on the sensor specified as well as the method of attachment (together as a system).

Stud mounted (or epoxy mounted) sensors are often able to utilize the entire high-frequency measurement capability of a sensor because this technique will maximize the surface contact of the sensor on the machine.

Conversely, a probe tip-mounted sensor has very little surface area contact with the machine surface and offers very little high-frequency accuracy above 500 Hz (30,000 CPM).

The low-frequency response may be accurately obtained by all of the below-illustrated techniques because the low frequency is not based on the mounting system resonance of the sensor and attachment method. The ability to measure low-frequency vibrations will be a function of the sensor's specified capability to measure a given low frequency. It is not dependent on the mounting technique chosen.

The following chart offers a general guideline for the range of mounting techniques available, and the corresponding high-frequency response expectations*:

*depending on the specified high-frequency response of individual sensors