MOTOR FIN MOUNT PADS FOR WIRELESS SENSORS

CTC’s Motor Fin Mount Pads offer a specialized solution tailored for fin-cooled motors where direct access to the bearing housing is not available. This proprietary design, introduced in 1995, was developed after analyzing the dimensions of hundreds of fin-cooled motors and has remained unchanged due to its proven effectiveness. For over two decades, it has been a trusted tool for many vibration analysts.

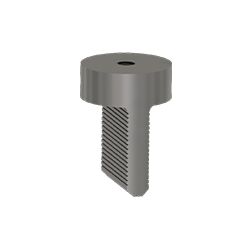

These pads include a 1/4-28 threaded hole for stud mounting and are magnetically responsive, making them ideal for route-based data collection.

Choosing the correct Motor Fin Mount Pad depends on the specific dimensions of your motor’s fins. The probe must fit snugly between the fins, with its base making contact with the motor casing to ensure proper vibration transmission to the sensor. For motors with more than ½ inch of space between fins, thicker ½-inch probe pads are available, which also help minimize adhesive use.

To install, apply adhesive to both the sides and the base of the probe section (note: the surface is textured to improve adhesion). Press the pad firmly between the fins, ensuring that the base touches the motor casing and the pad sits evenly across the fins.