ASCRIBO - Approved Strategic Partner

CTC is proud to partner with ASCRIBO Applied Sciences Inc., a trusted US-based predictive maintenance solutions provider. ASCRIBO combines advanced sensor technology, like the CTC ConnectSens™ wireless sensor, with autonomous algorithms and industrial IoT to offer cloud-connected, portable, smart vibration analyzers and online machine health monitoring solutions.

As an approved strategic partner, ASCRIBO offers several solutions that integrate seamlessly with the Connect wireless ecosystem:

ABLE Handy

Turn your smartphone into the world’s smallest and smartest portable vibration analyzer.

The ABLE Handy solution pairs CTC’s ConnectSens™ WS300 triaxial accelerometers with the free-to-download, Android device compatible ABLE Mobile app for portable data acquisition and analysis - any time, anywhere. This innovative solution eliminates the need for a ConnectBridge™ wireless gateway, saving you time and money when setting up you system.

With trends for overall vibration level (OVL in mm/sec), velocity spectrum, and bearing spectrums vs. fault frequencies, the ABLE Handy provides in-depth machine health data in the world’s smallest analyzer - your smartphone!

In-app analysis feature lets you know the general health status of your machinery and bearing faults at the very earliest stages.

Convenient plug-and-play functionality takes the hassle out of setup - simply download the free ABLE Mobile app on any Android device, pair your sensor via Bluetooth, and connect your Android device to the internet. That’s it - you’re ready to start monitoring.

* Mounting Hardware, Sensor, and Software all sold separately

ABLE Patrol S

ABLE Patrol S is ASCRIBO’s most advanced portable data collection solution, built on four components:

| CTC ConnectSens™ WS300 wireless triaxial sensors | |

| ABLE Patrol S, free-to-download Android mobile app | |

| Advanced cloud-based vibration analysis algorithm | |

| ABLE Monitor, a web-based user interface |

This innovative solution eliminates the need for a ConnectBridge™ wireless gateway, saving you time and money when setting up you system.

The ConnectSens™ WS300 wireless sensors collect the data and transmit to ABLE Patrol S in your cell phone or tablet. The ABLE Patrol S then pushes the raw data to the internet, to be analyzed autonomously by the algorithm in ASCRIBO servers. The data is analyzed within seconds and your vibration analysis report is sent to your user account on ABLE Monitor, the web-based user interface.

ABLE Patrol S offers advanced analyzing capabilities to detect and define bearing faults from very early stages, as well as balancing issues, misalignment and much more. Its cutting-edge algorithmic capabilities also enable its use on very slow rotating machines, as low as 2 RPM.

Convenient plug-and-play functionality takes the hassle out of setup - simply download the free ABLE Monitor app on any Android device, pair your sensor via Bluetooth, and connect your Android device to the internet. That’s it - you’re ready to start monitoring.

ABLE System

ABLE System, an innovative 24/7 online machine health monitoring solution, uses a proven, cloud-based autonomous vibration analysis algorithm for advanced predictive maintenance.

The ABLE System includes:

| CTC ConnectSens™ WS300 wireless triaxial sensors | |

| CTC ConnectBridge™ wireless gateway | |

| Advanced cloud-based vibration analysis algorithm | |

| ABLE Monitor, a web-based user interface |

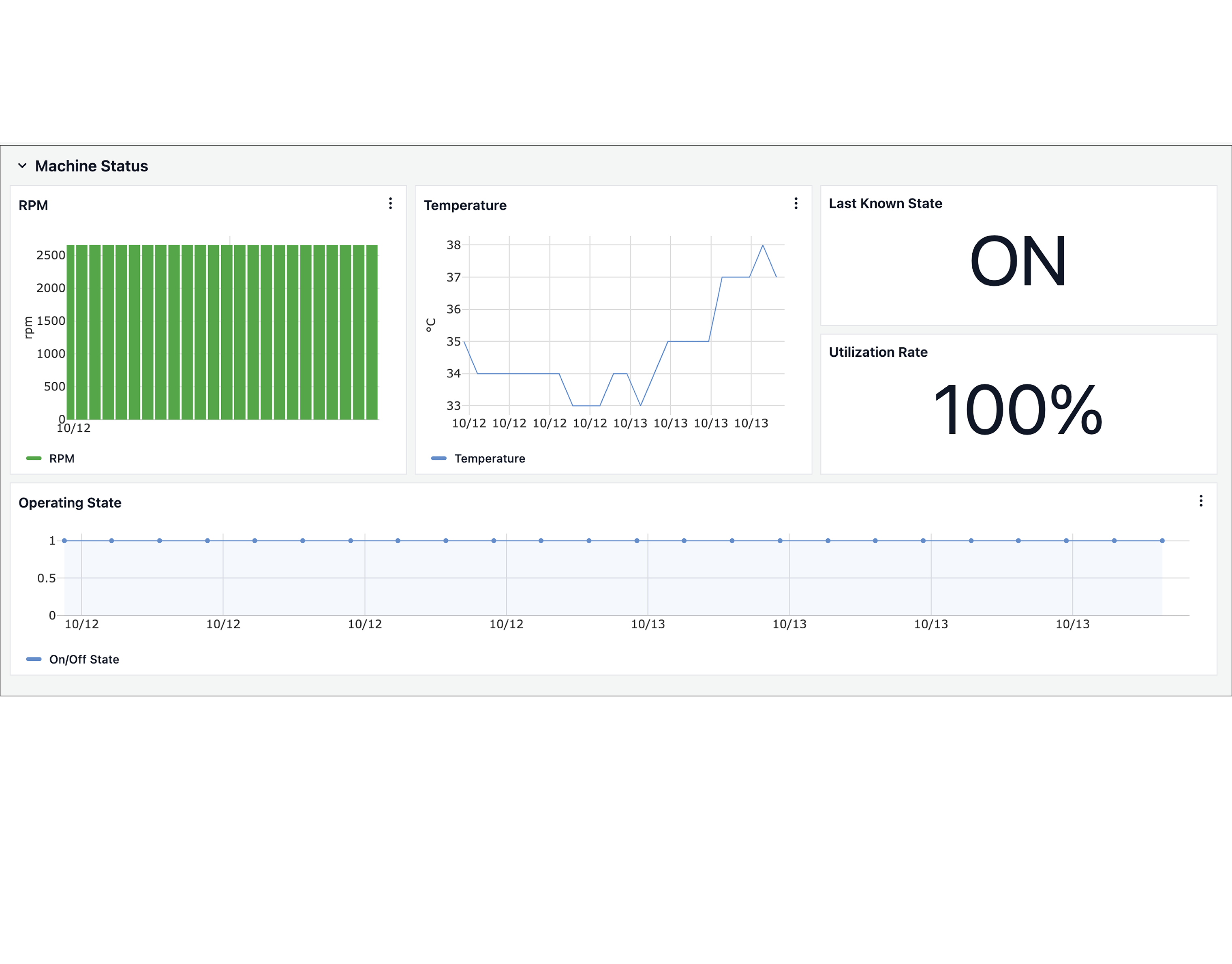

The autonomous algorithm quickly analyzes three axes of raw vibration plus temperature data within seconds, and the results are then instantly viewable in the ABLE Monitor app for easy-to-understand, actionable machine health data.

The cutting-edge algorithmic capabilities offered by the ABLE System also enable its use on very slow rotating machines, as low as 2 RPM.

Get started quickly and easily with hassle-free setup: permanently mount your ConnectSens™ wireless sensors via mounting pads or studs, install your gateway, then connect your gateway to the internet for sensor-to-cloud communication. That’s all you need to get autonomous data from your critical machines, 2/47.

With ABLE System, you’ll harness powerful machine health data and tools including:

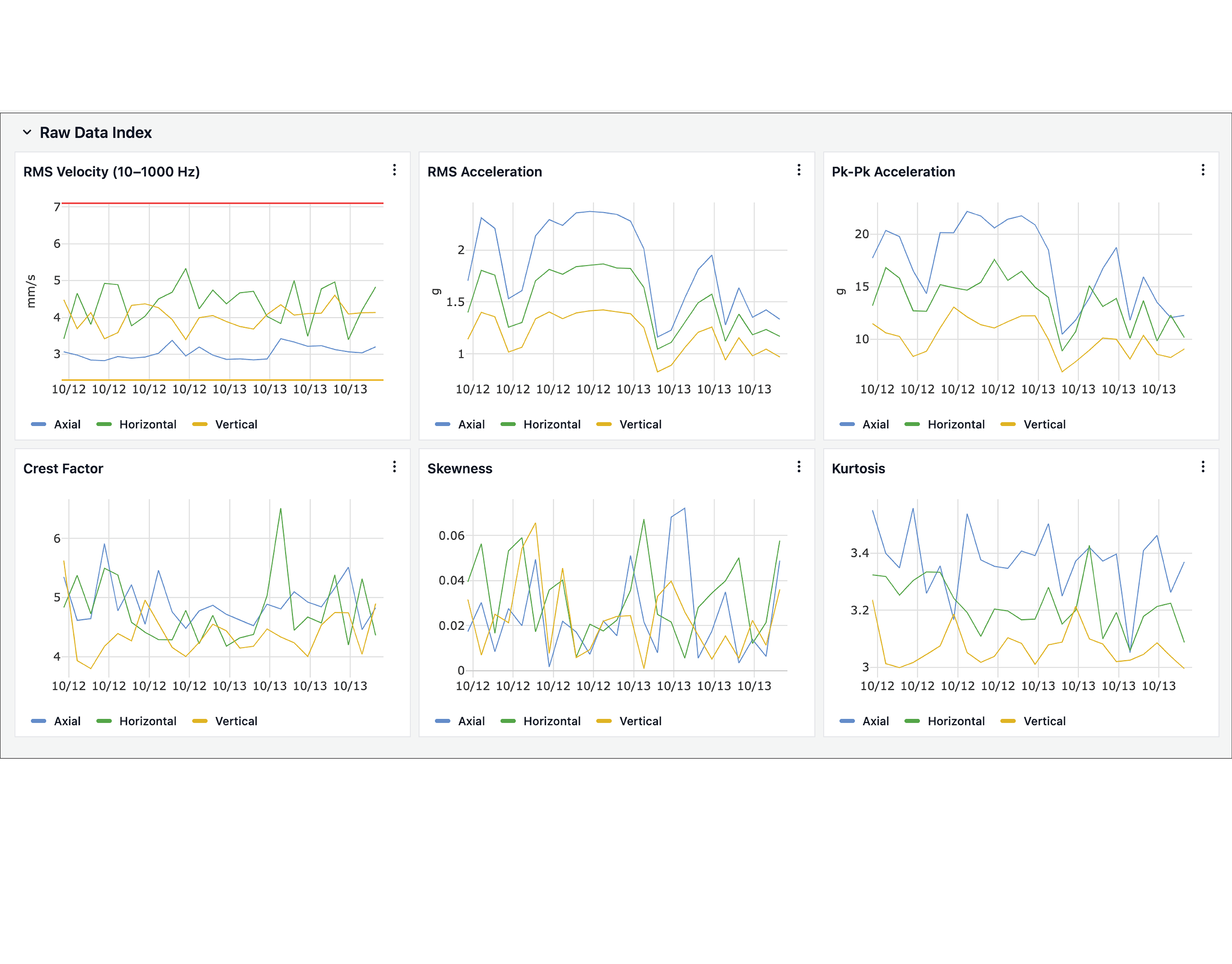

Raw Data

| RMS Velocity |

| RMS Acceleration |

| Pk-Pk Acceleration |

| Crest Factor |

| Skewness |

| Kurtosis Bearing Status Trends Over Time |

Diagnostic Visualization Tools

|

Time Domain Signal |

|

Spectrum |

|

Circular Plot |

|

Waterfall Plots |

|

And more |

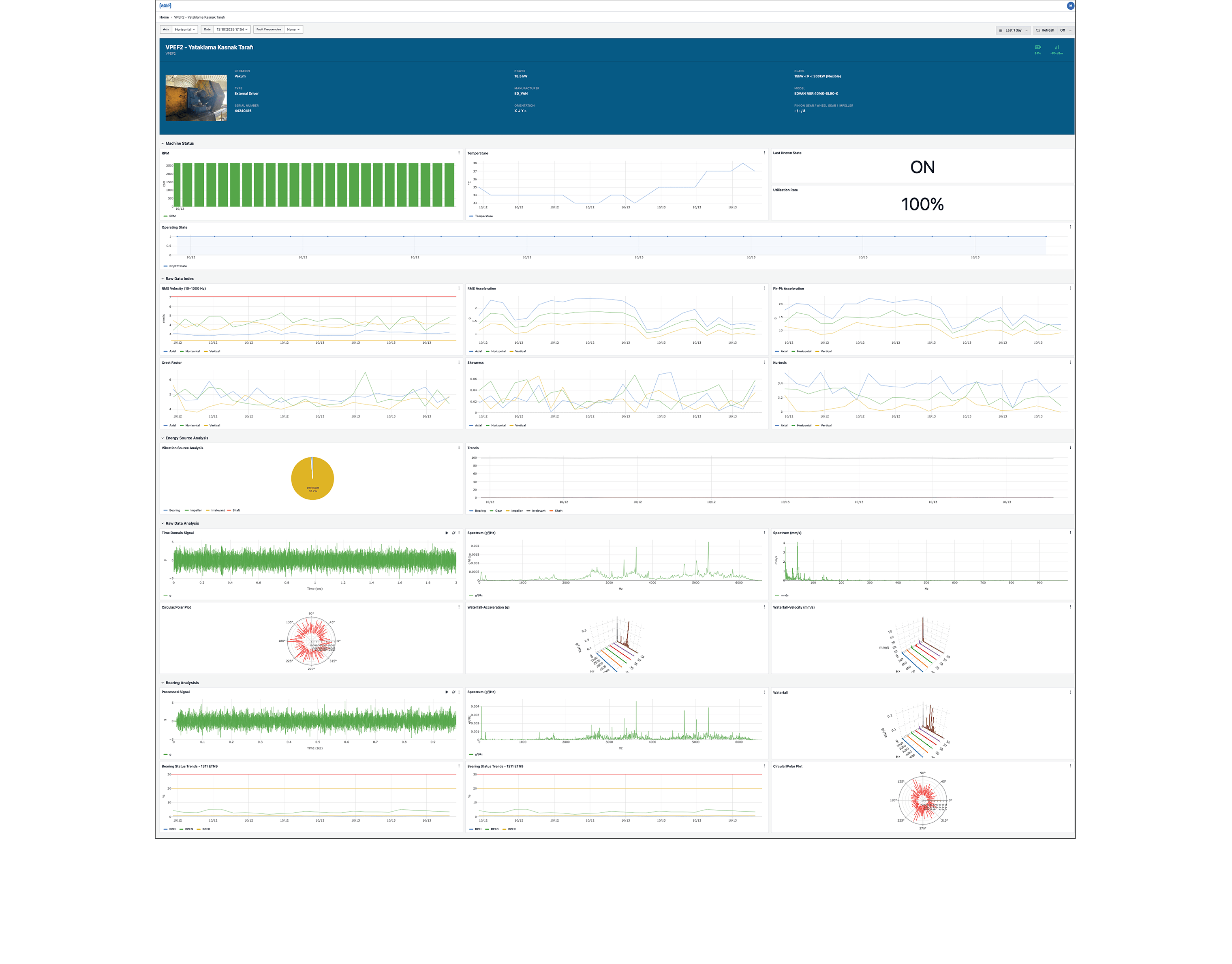

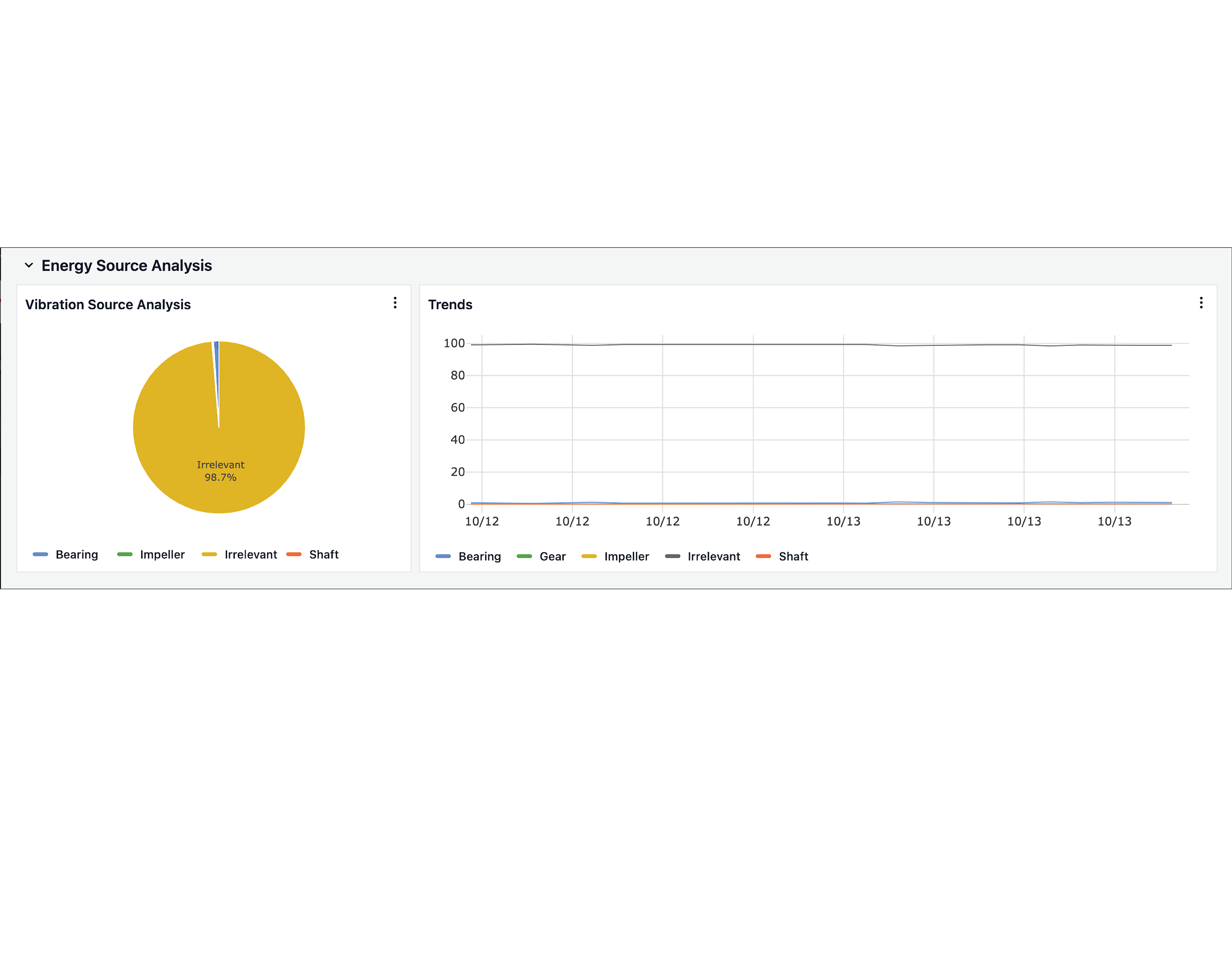

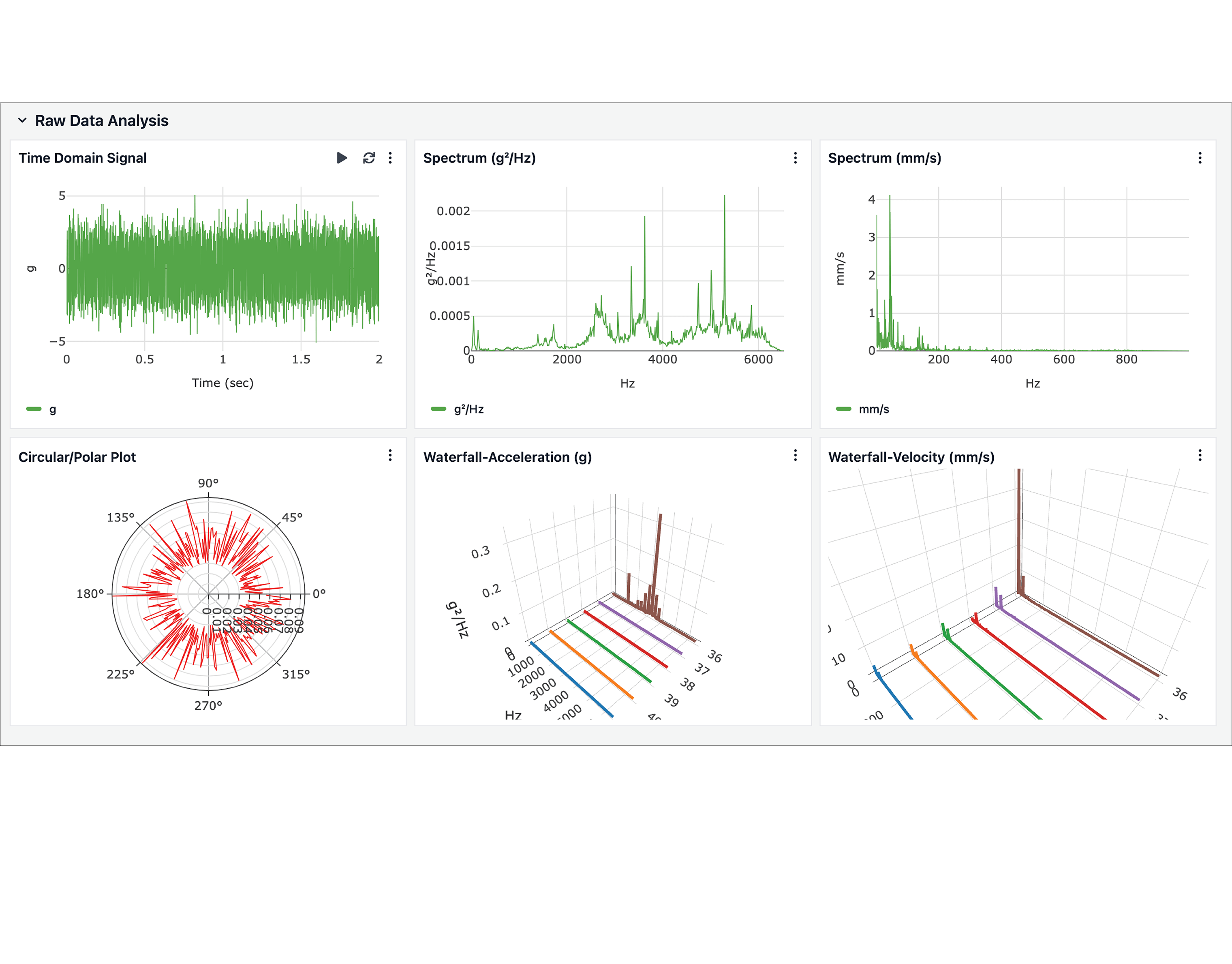

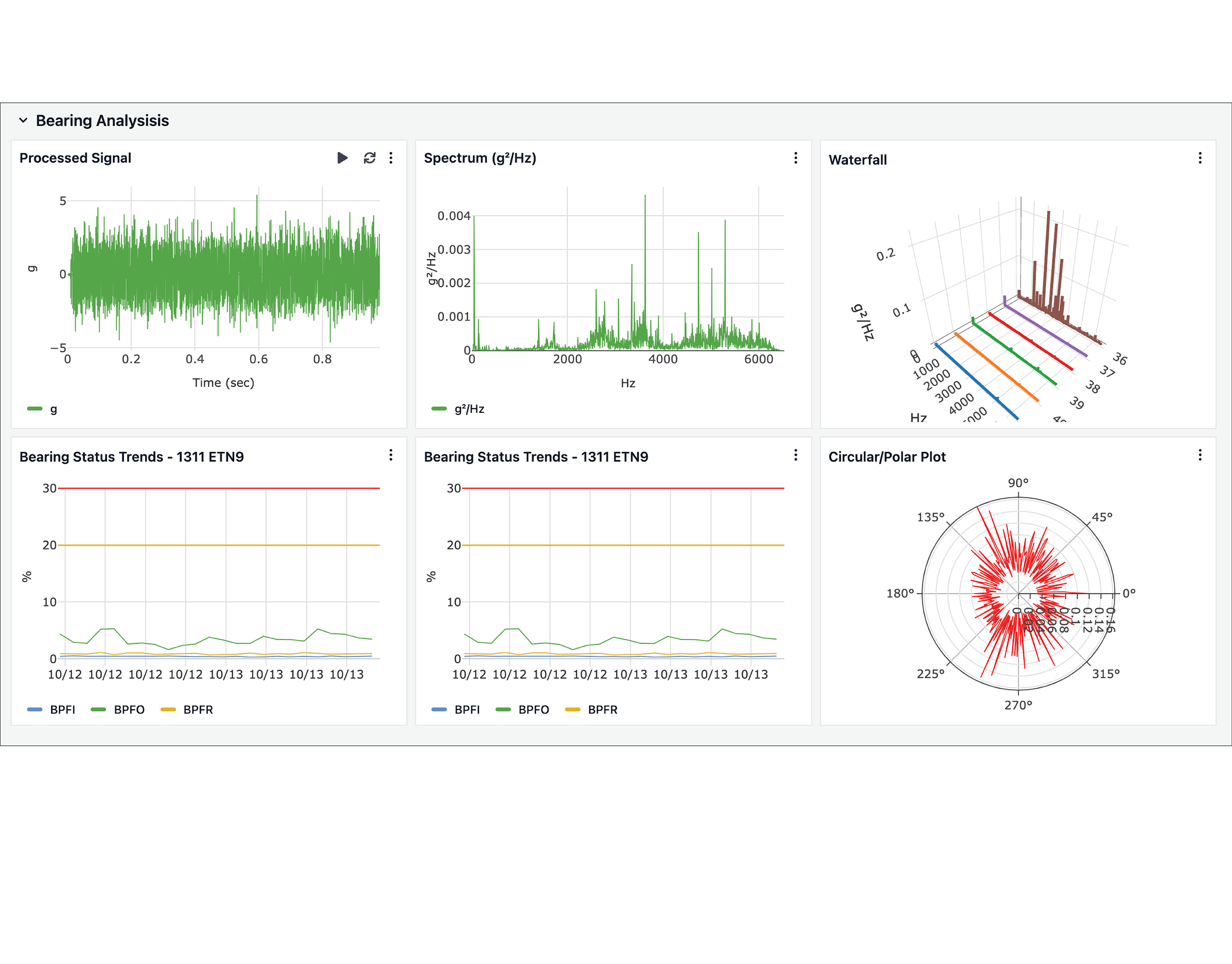

ABLE Monitor Data Examples

ABLE Monitor, the web-based user interface for the ABLE System, gives you clear, concise, easy-to-understand data at your fingertips. Check out the slideshow below for examples:

ASCRIBO ABLE Monitor Software - Project Dashboard

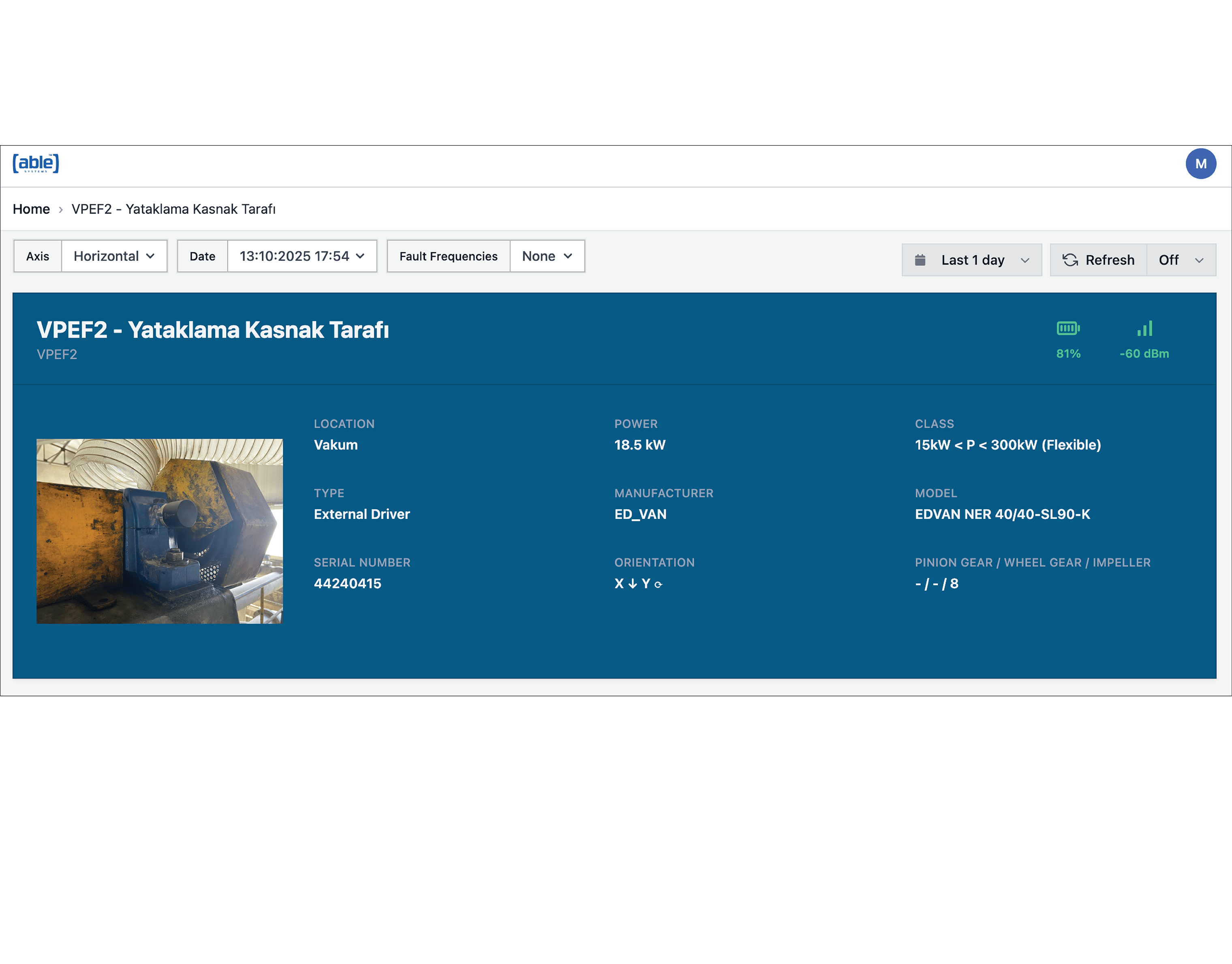

ASCRIBO ABLE Monitor Software - Machine Overview

ASCRIBO ABLE Monitor Software - Machine Status

ASCRIBO ABLE Monitor Software - Raw Data Index

ASCRIBO ABLE Monitor Software - Energy Source Analysis

ASCRIBO ABLE Monitor Software - Raw Data Analysis

ASCRIBO ABLE Monitor Software - Bearing Analysis

Why Choose ASCRIBO + CTC?

|

Academically Proven Algorithm The cutting-edge technology turns complex machine vibration and temperature readings into easy-to-understand data |

|

Simple, Seamless Setup The ABLE plug-and-play solutions pair quickly and easily with CTC hardware so you can start collecting data in minutes |

|

Options to Fit Every Application Whether you're looking for a portable data analysis solution or a permanently-installed, continuous machine health monitoring system, ABLE offers a system to fit your needs |

|

American Engineering Excellence Pair industry-leading, US-based software with the unmatched quality of CTC's US-manufactured hardware for repeatable, reliable data acquisition |

Case Study

PARTNERING WITH CTC AND ASCRIBO TO TURN DATA INTO ACTIONABLE PLANT MAINTENANCE

CTC’s distribution partner, ASCRIBO, performed analysis on a bearing housing on the pulley side of a vacuum fan using CTC’s WS300 triaxial wireless sensor and the ABLE System.

Data was collected in 3 axes at 60-minute intervals. The root cause of the failure was determined to be an imbalance in the fan rotor, and it was found that this static force degraded the bearing on the pulley side. The early detection of such failures plays a critical role in preventing downtime and reducing overall maintenance costs.

| Industry and Use Case Paper Production Facility |

| Hardware WS300 Series ConnectSens Wireless Sensors and ConnectBridge Wireless Gateway |

| Application Bearing housing on pulley side of vacuum fan |

| Software ABLE Monitor by ASCRIBO |

Ready To Get Started With ASCRIBO?

Fill out this form and a CTC Sales Representative will be in touch to schedule a live demo of ASCRIBO platforms.