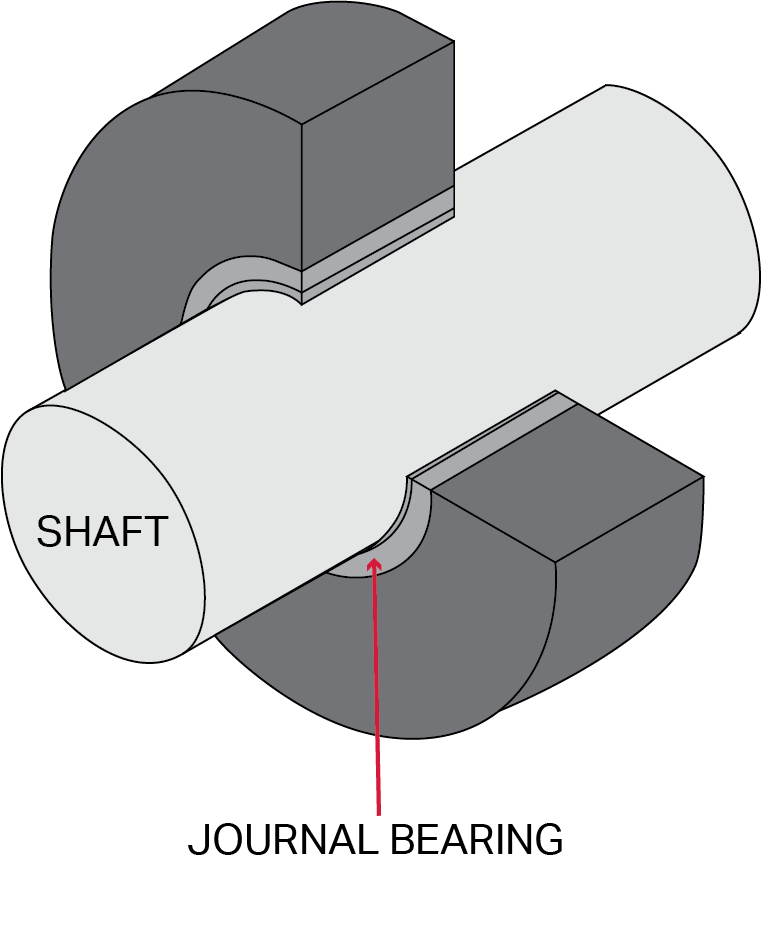

JOURNAL BEARING MONITORING GUIDE

A Journal Bearing, or Fluid Film/Sleeve Bearing, is a type of bearing in which the shaft is suspended in a pressurized regime of oil. These are used on very large or powerful rotating machines to provide damping of the vibration to pass through critical speeds and suppress instabilities caused by loads or natural frequencies of the housing. This damping of the vibration protects the rest of the production line from the extreme force generated by the rotating element, but it also makes it difficult for regular accelerometers to get accurate vibration data of the shaft while mounted on the machine housing.

Inductive Proximity Probes (Eddy Current Probes) are non-contact displacement sensors used to determine the absolute displacement between the tip of a sensor and a conductive target material. These probes use the fluctuations induced in an electromagnetic field generated by the probe system to determine the bearing shaft position relative to the bearing casing and the dynamic vibration of the rotating shaft. Industrial Proximity Probes are most commonly used in petrochemical and energy production, specifically in turbines and reciprocating compressors that utilize Journal Bearings.

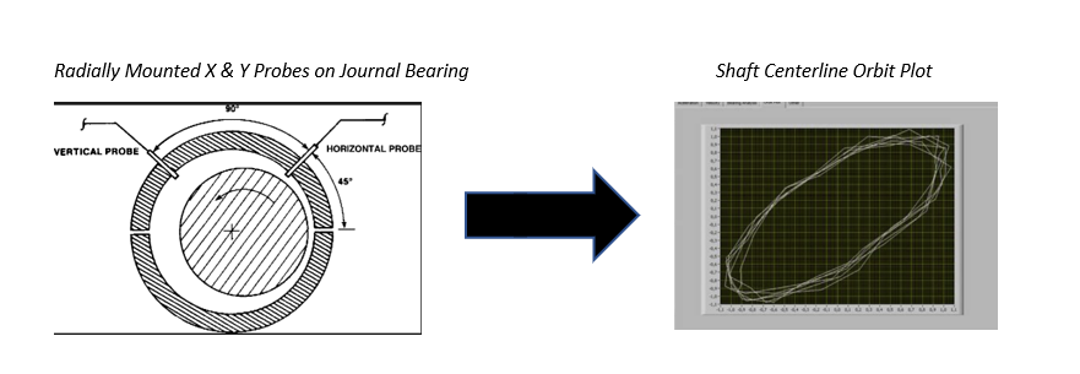

Proximity Probes provide very accurate information on the position and vibration of the journal bearing shaft relative to the rest of the machine housing. For typical radial condition monitoring applications, two probes will be mounted perpendicular to the shaft 90° apart from one another to measure the X and Y axes. The vibration of the shaft will be measured as a variable DC voltage that simulates an AC vibration signal.

Using this position/vibration data from both axes, analysts can create an orbit that can be used to measure the total vibration of the shaft’s centerline as it rotates in the bearing sleeve. An orbit will provide the peak-to-peak displacement and direction of the vibration relative to the shaft centerline. The location of the shaft centerline within the bearing sleeve can also be measured with radially mounted probes. The DC portion of the voltage signal is proportional to the space between the probe tip and shaft surface. This measurement is critical in knowing the location of the shaft within the bearing housing and preventing metal contact between the shaft and bearing sleeve which could have catastrophic results.

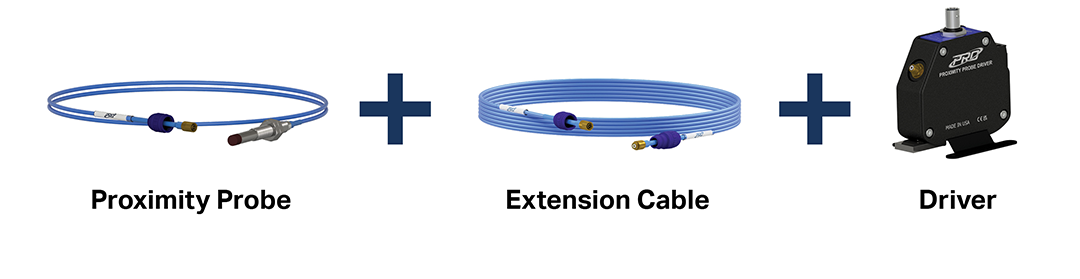

What is a Complete Proximity Probe System?

Eddy Current Proximity Probe Systems are an effective way to monitor Journal Bearings. A complete Proximity Probe System consists of a Proximity Probe, Extension Cable, and a Proximity Probe Driver.

Standard vs. Hazardous Rated Systems

All PRO Line Proximity Probe Systems are available in both standard and hazardous-rated configurations.

Optional regulatory approvals for hazardous-rated systems include CSA, ATEX, IECEx, and CE. Please note - these certifications require the intrinsically safe barrier driver to be mounted in a NEMA 4x and/or IP6x enclosure.

Selecting Your Ideal Proximity Probe System

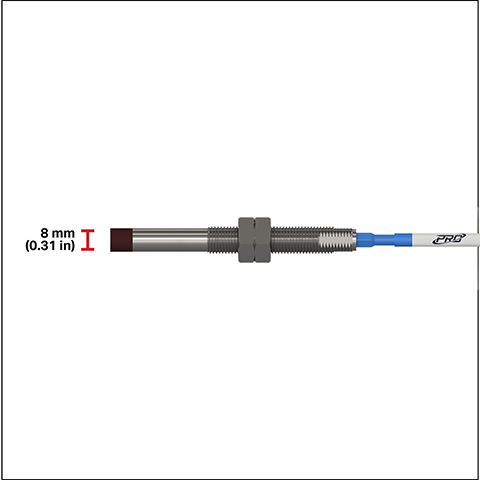

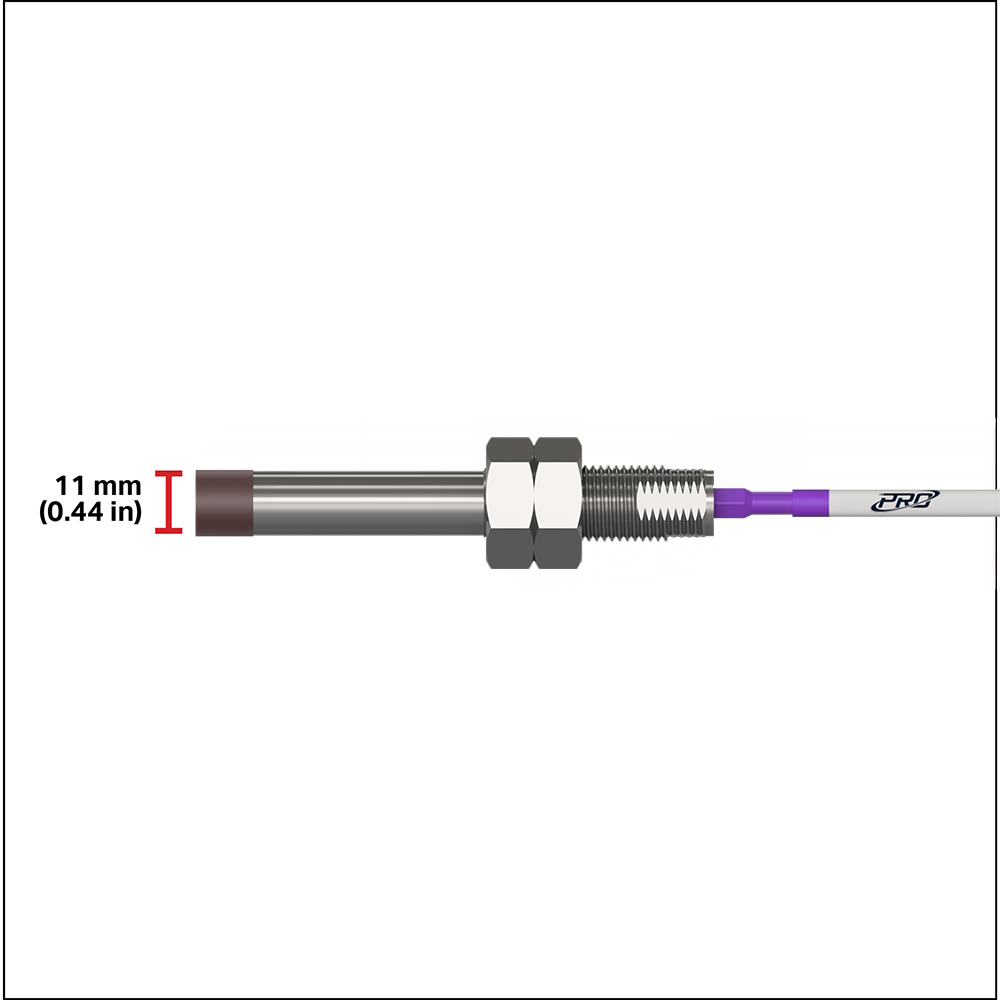

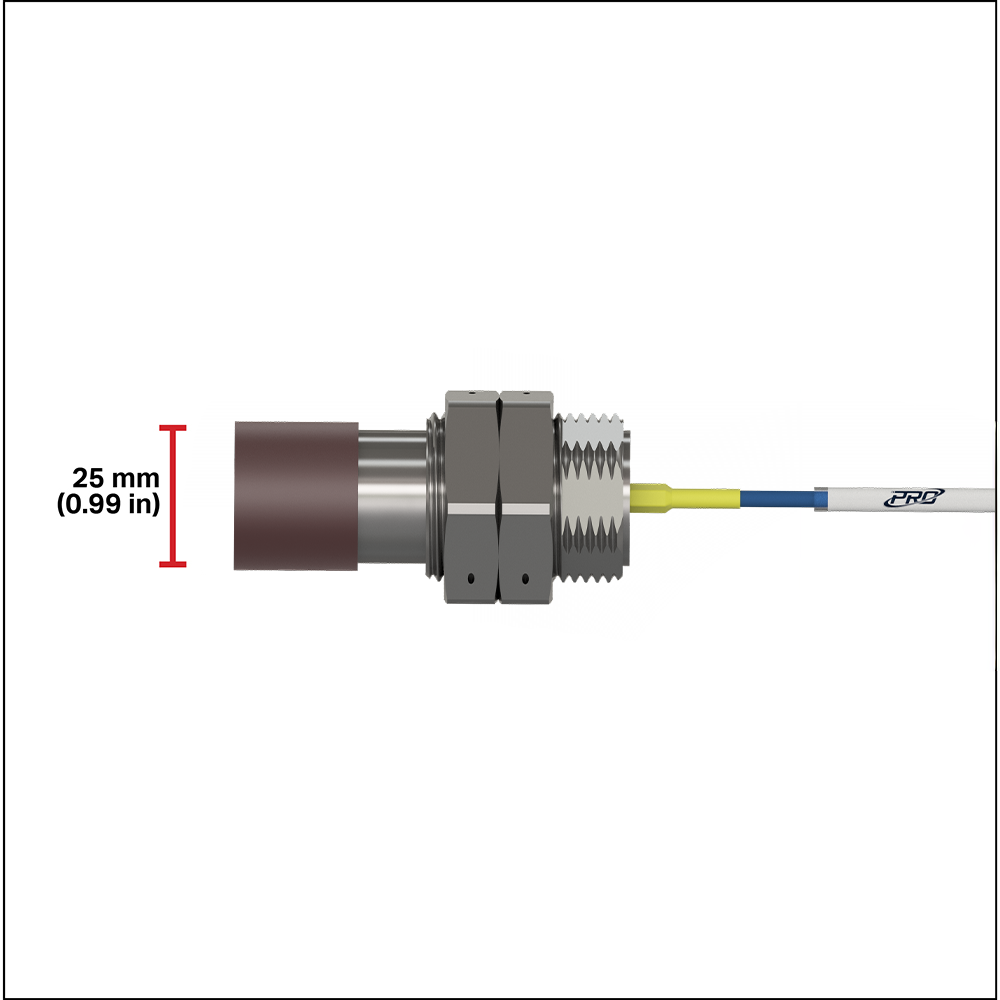

CTC offers a complete line of proximity probe systems designed, built, and tested to endure prolonged use in the harshest industrial environments. PRO Line Proximity Probe Systems are available in FFV, 8 mm, 11 mm, and 25 mm systems. The variety of probe sizes offered allows for accurate and precise displacement measurements as well as shaft speed/phase analysis. Complete PRO Line Proximity Probe Systems are compatible with all standard condition monitoring software, including Alta Solutions, Bently Nevada, and TWave software.

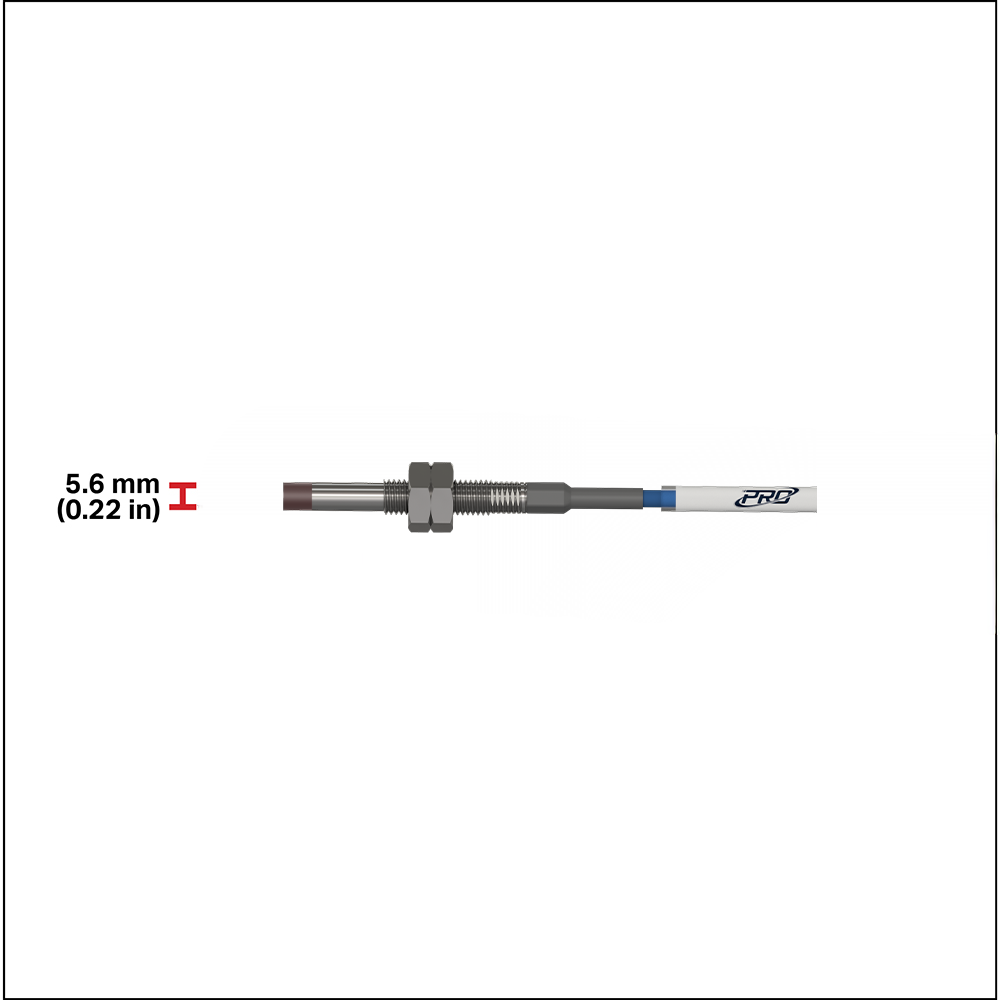

Probe Tip Sizes

FFV Probe Tip

For displacement gaps of 10-70 mils

Output Sensitivity:

-200 mV/mil (-7.87 V/mm)

Note - FFV probes may be used for any applications within their linear range when clearance is an issue. They are the only probes we recommend for shafts with a diameter less than 2 inches. They are also used for many general purpose applications for larger shafts.

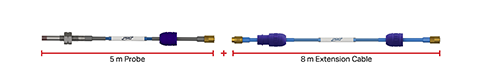

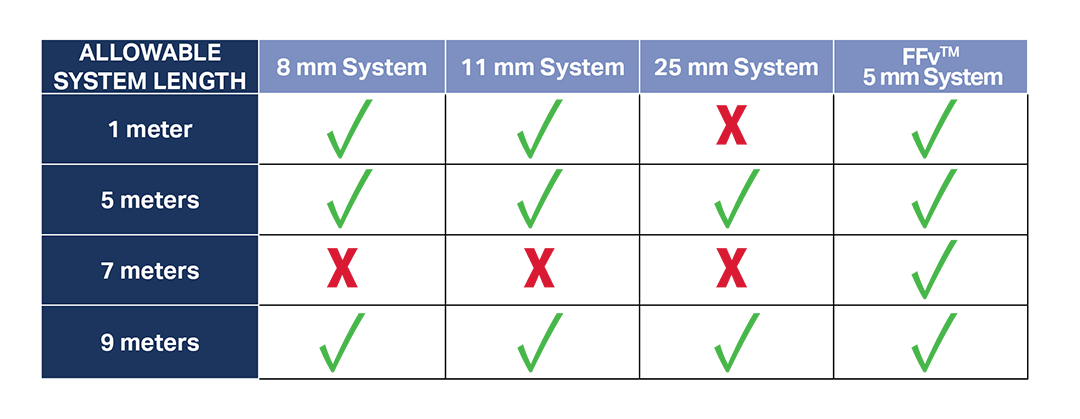

System Length

The length of a proximity probe plus extension cable must equal one of the system lengths allowed for your probe size selection.

Refer to the chart below to determine the system length that is best for your application:

Other Important Considerations

Cable Jacket

Standard FEP Jacket or Armor Jacket available

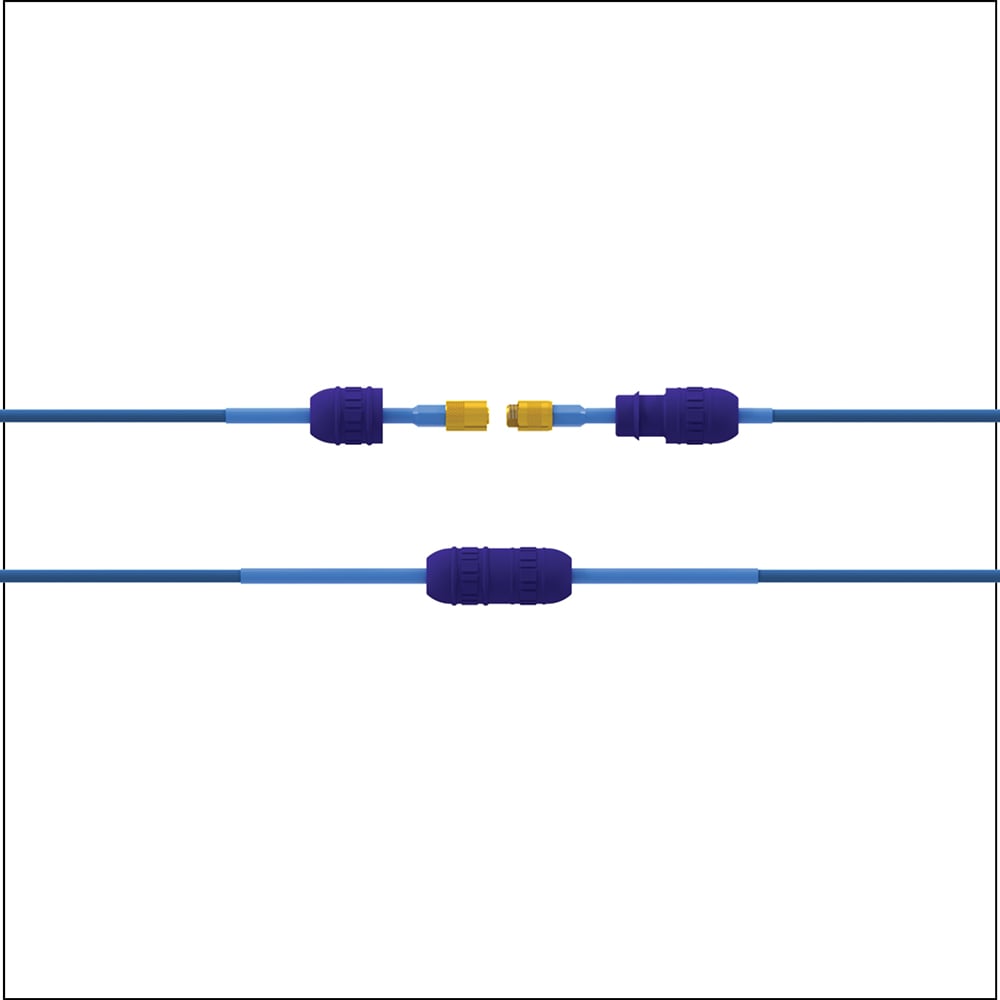

Connector Protectors

Required for hazardous applications

Provide an added layer of durability for the connection between your probe and extension cable

Mounting Style

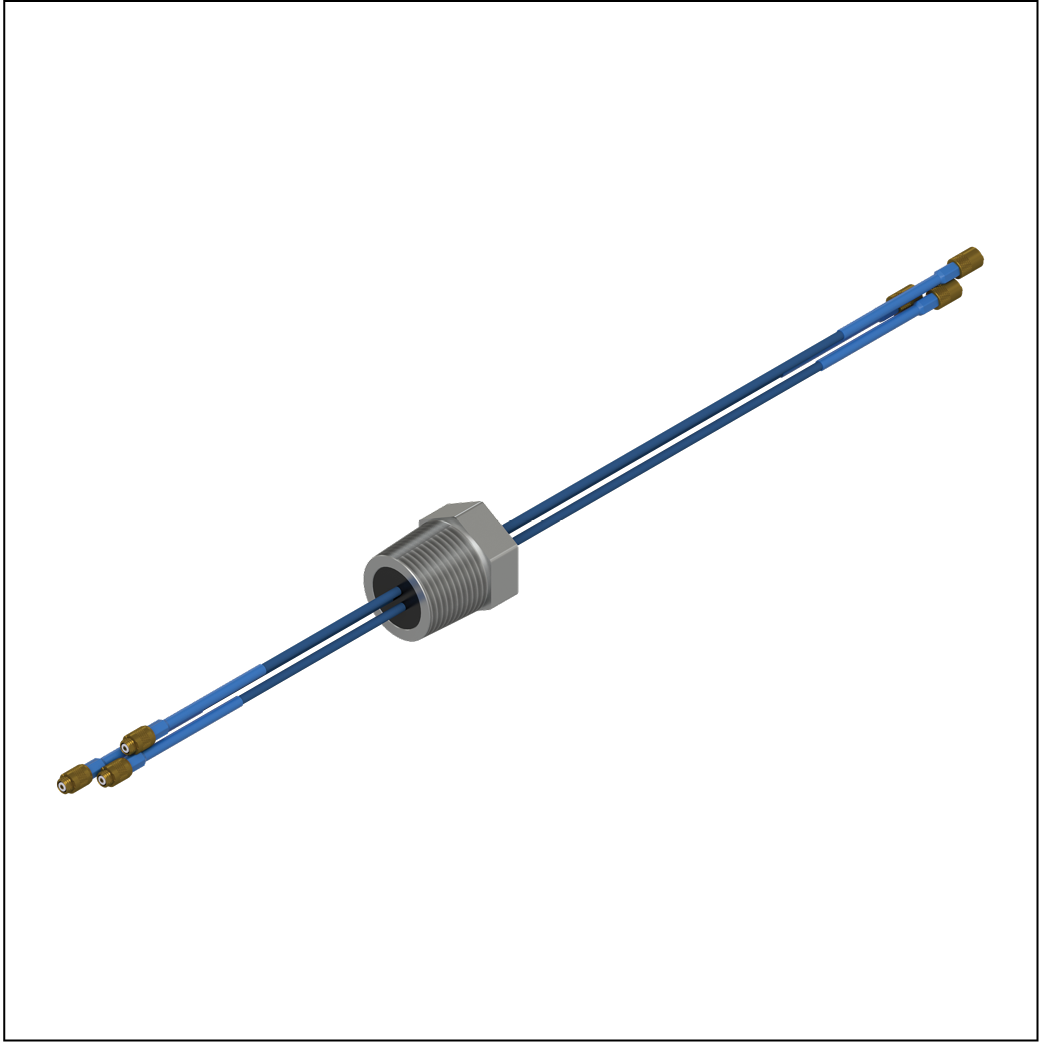

Standard internal and external brackets and bushings as well as external housing for "reverse mount" probe systems available

1-11.5 NPT Fittings with Factory-Installed Proximity Probe Extension Cables, rated to 400 PSI for high pressure applications.

Available with single-sided or double-sided NPT fittings, with FEP or Armor Jacketed cables.

Proximity Probe Mounting

In this method, the probe will be threaded into the bushing, bracket, or bored-out hole in the machine housing and screwed down until the probe tip is close to the target shaft. A non-metallic feeler gauge is required and should be the size of the desired gap between the probe and the target. For example, 50 mils is a common gap selection for 8 mm probe systems since it sits near the midpoint of the system's linear range of 10-80 mils. The probe should be carefully turned into the housing until it is lightly touching the feeler gauge. Once the probe gap is set, the probe should be locked into place with the locknuts on the probe casing.

The first step for this method is to connect the Proximity Probe to its extension cable and driver. Apply -24V to the driver and connect a digital multimeter to the voltage output terminal. Insert the probe into the tapped mounting hole. As the probe tip is threaded through the hole, the sensor's output voltage will remain low or give a false reading because it is sensing the surrounding materials of the machine housing. As the probe extends through the housing, the output voltage will increase to its maximum point and then decrease as it approaches the observed surface. The output voltage from the probe system should correspond with the calibration curve that is published on the calibration certificate. Use the linearization table on the calibration certificate to gap the probe to the desired distance.

Proximity Probe Driver Selection

PRO Voltage Drivers also come supplied with a three-wire output terminal block to connect to a protection system.

CTC also offers four-wire Proximity Probe Drivers with a scaled 4-20 mA output proportional to either gap displacement, radial vibration, and axial position.

The dynamic voltage signal is available on all proximity probe drivers via the BNC Jack located on the unit.

Reference the following diagrams to determine the best driver selection for your application:

VOLTAGE DRIVER:

The voltage drive has a dynamic voltage output that is compatible with industry-standard continuous vibration monitoring systems and is the format specified in API Standard 670. The dynamic voltage output is proportional to the DC gap between the target material and probe tip.

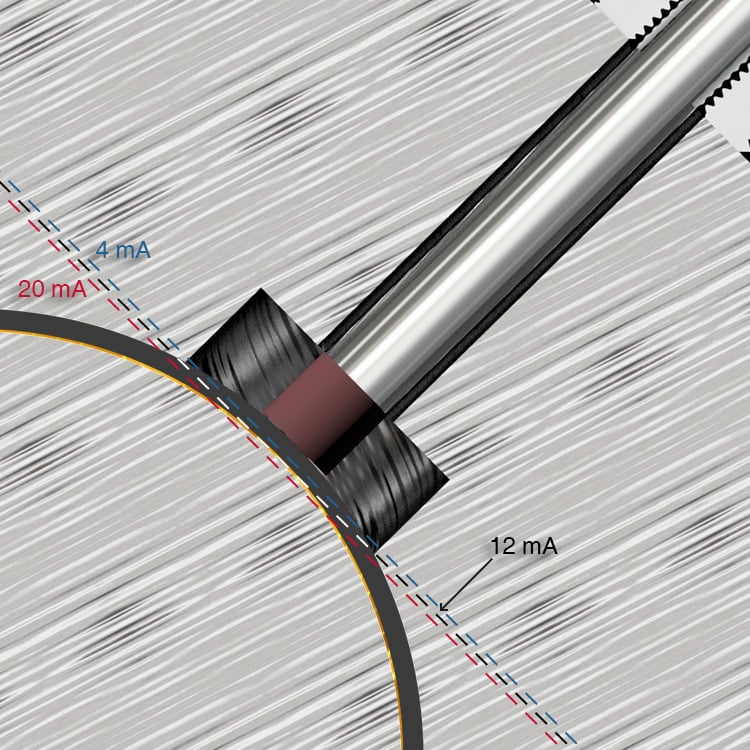

4-20 mA DRIVERS:

4-20 mA Drivers Proportional to DC Gap:

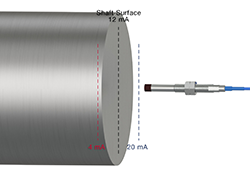

Probe showing proportional output for the 4-20 mA signals. With shaft surface at 50 mils, 4-20 output is 12 mA. If the gap increases to 70 mils, 4-20 output will be 16 mA.

*Please note: The numbers referenced above are for use with an 8 mm probe.

Radial Application Drivers:

In radial applications, the probe drivers select the average shaft surface distance and the 4-20 is proportional to the overall peak to peak vibration in mils around the average surface of the shaft.

Axial Application Drivers:

In the thrust position the probes auto range to the face of the shaft or thrust collar, and the 4-20 is proportional to the positive or negative vibration away or toward the probe, as shown.

Proximity Probe Driver Enclosures

CTC offers our PXE Proximity Probe Driver Enclosures in both fiberglass and stainless steel options. PXE Enclosures are NEMA 4X rated to ensure your proximity probe drivers are protected from dirt, dust, oil, and water.

24V power supply and/or terminal blocks are also available as configurable options for the PXE150 and PXE250.