Case Study: Boiler Feed Pump Impact Testing

Thank you to our friends at JetTech Mechanical for providing the data for this case study

View the printer-friendly PDF version of the Boiler Feed Pump Impact Testing Case Study

Introduction

Our friends at JetTech Mechanical were commissioned to collect and evaluate impact (modal) test data for the Sulzer Boiler Feed Pump bearing housings and shaft. The intent is to determine whether any structural or rotor natural frequencies are coincident with operating speeds, harmonics, or hydraulic excitations such as vane pass frequency.

Equipment

The subject machine is a Sulzer multistage boiler feed pump with the following key characteristics:

|

SULZER FQ-360-GSG BOILER FEED PUMP |

|

Rated Power: ~3000 HP |

|

Speed: 60 Hz |

|

Actual Operating Speed: 3587 RPM |

|

Stages: Eight (8) |

|

Nominal Synchronous Speed: 3600 RPM |

|

Actual Measured Speed (Keyphasor): 3587 RPM |

|

Impeller Configurations Evaluated: 5-vane and 7-vane designs |

Hardware

JetTech Mechanical utilized the following hardware to perform impact testing:

AC192-1D

Compact accelerometer, 100 mV/g, ±10% sensitivity tolerance

MH114-3A

Multipurpose mounting magnet, 50 lbs. pull strength

CB103-K2C-010-F-SF

CB103 two-conductor cable with K2C two-socket MIL-style connector on the left, F BNC molded plug connector on right, and SF breakaway safety feature; 10 ft. length

BETAVIB VibWorks King

Data collector

Operating Frequencies

Based on the measured operating speed of 3587 RPM, the following forcing frequencies apply:

|

1x Running Speed: 3587 CPM |

|

2x Running Speed: 7174 CPM |

|

5x Vane Pass Frequency (5-vane): 17,935 CPM |

|

7x Vane Pass Frequency (7-vane): 25,109 CPM |

Impact Test Summary

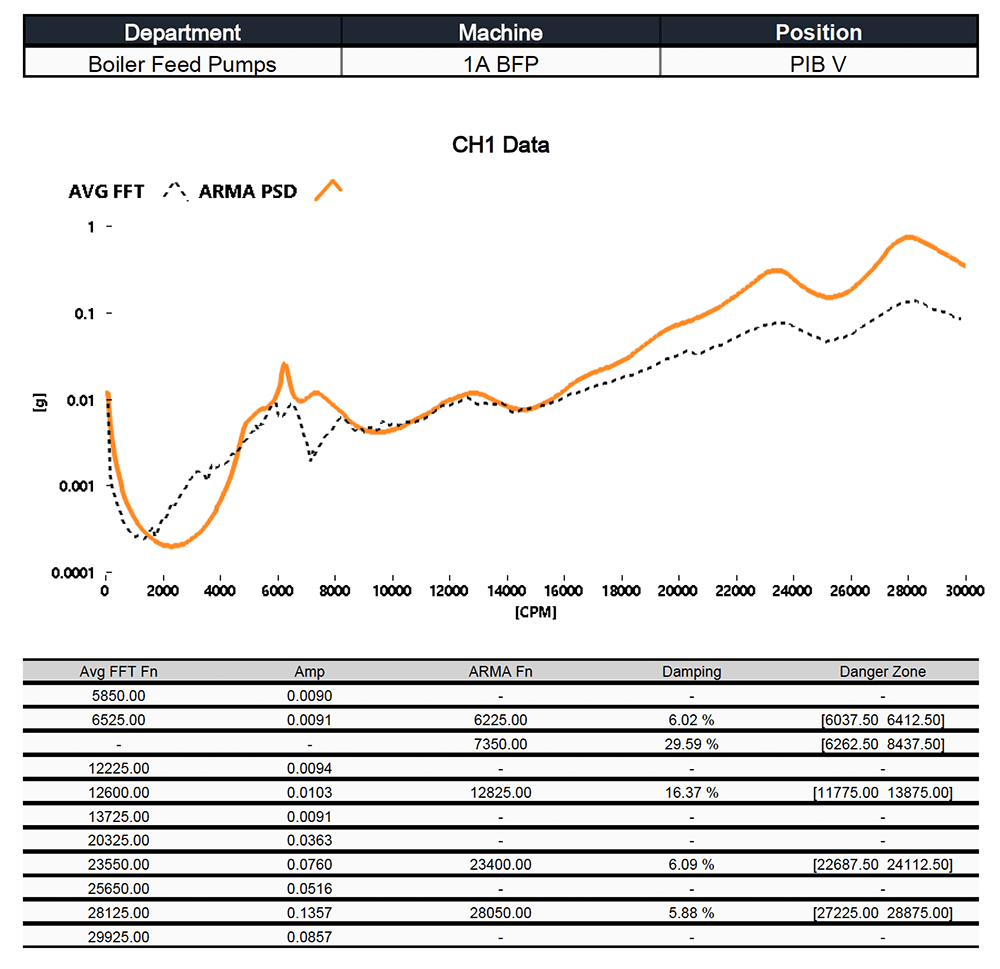

Impact testing identified multiple structural resonances within the pump bearing housings and shaft system. Of particular importance is a lightly damped vertical structural resonance centered near 25,800 CPM, with an identified danger zone spanning approximately 25,160 to 26,440 CPM.

Additional resonances were identified near 1x and 2x running speed ranges; however, these were secondary in significance compared to vane pass interaction.

Impact Test Results

Impact testing conducted on the pump bearing housings and shaft system revealed several structural resonances. Notably, there is a lightly damped vertical structural resonance centered at approximately 25,800 CPM. This resonance is considered critical, as it defines a “danger zone” spanning from about 25,160 to 26,440 CPM, where structural response is significantly amplified.

Additional structural resonances were also detected near both the 1x and 2x running speed ranges. However, these resonances are of secondary importance when compared to the pronounced interaction occurring at the vane pass frequencies.

Please see the appendix at the end of the blog post for impact test data

Relationship to Operating Vibration Data

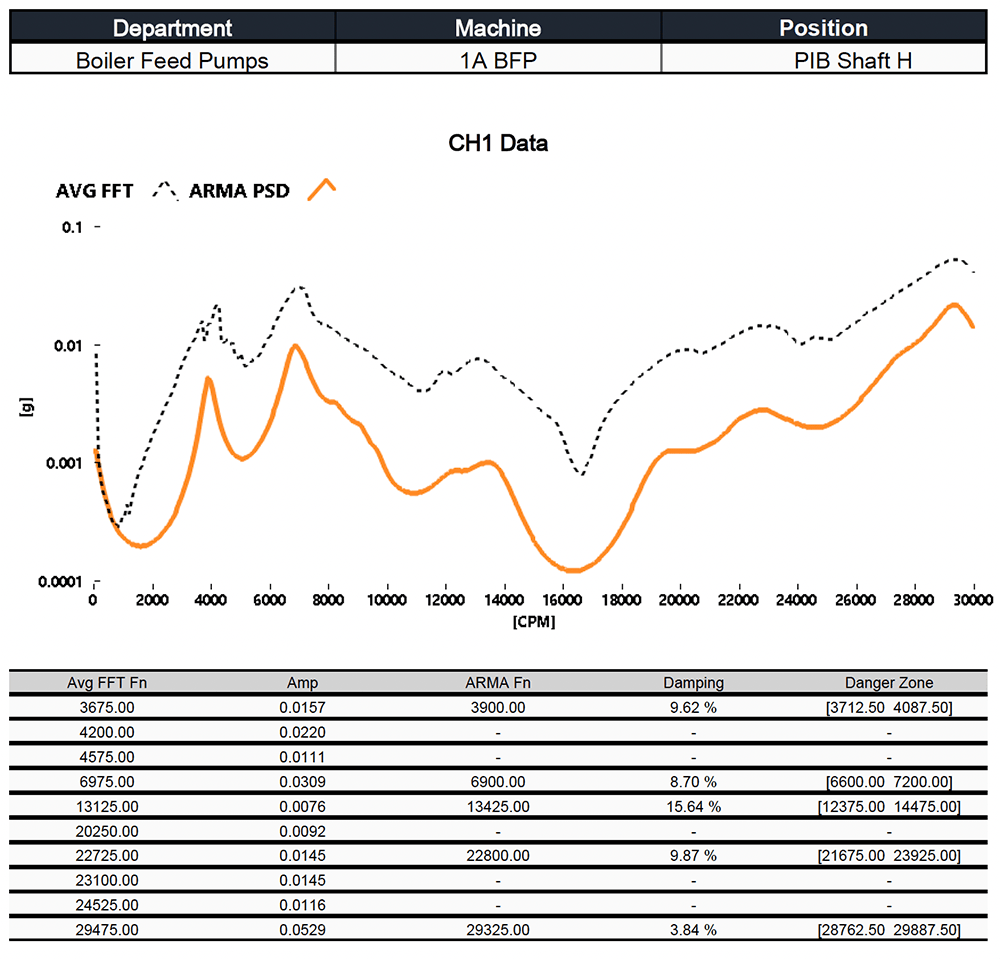

JetTech Mechanical’s operating vibration measurements show higher vibration levels at the 7x vane pass frequency, with the Pump Inboard Bearing (PIB) vertical direction being the most affected.

At the operating speed of 3587 RPM, the 7x vane pass frequency (25,109 CPM) is located right next to the identified vertical resonance range. Because this mode has low damping, the structure responds with strong amplification when subjected to hydraulic forces from the vane passes.

Root Cause Assessment

The primary factor contributing to elevated PIB vertical vibration is attributed to a resonance phenomenon established between the hydraulic forcing frequency of the 7-vane impeller and a vertical structural mode of the pump casing and bearing pedestal assembly. This scenario is not associated with imbalance, misalignment, or bearing defects, as these conditions do not typically elicit excitation at vane pass frequencies.

Risk Assessment

Operating under this resonance condition may lead to:

- Accelerated bearing degradation

- Fretting and loosening at pedestal interfaces

- Fatigue-induced cracking in bearing housings or casing components

- Increased maintenance requirements and diminished equipment reliability

Primary Recommendation

Transition to a 5-vane impeller configuration to shift the vane pass excitation to 17,935 CPM, thereby avoiding the identified vertical resonance.

Secondary Mitigation Measures

- Inspect, and if necessary, re-grout inboard bearing pedestal

- Verify proper torque of hold-down bolts and assess soleplate condition

- Confirm operation in proximity to the Best Efficiency Point (BEP)

_________________________________________________________

APPENDIX

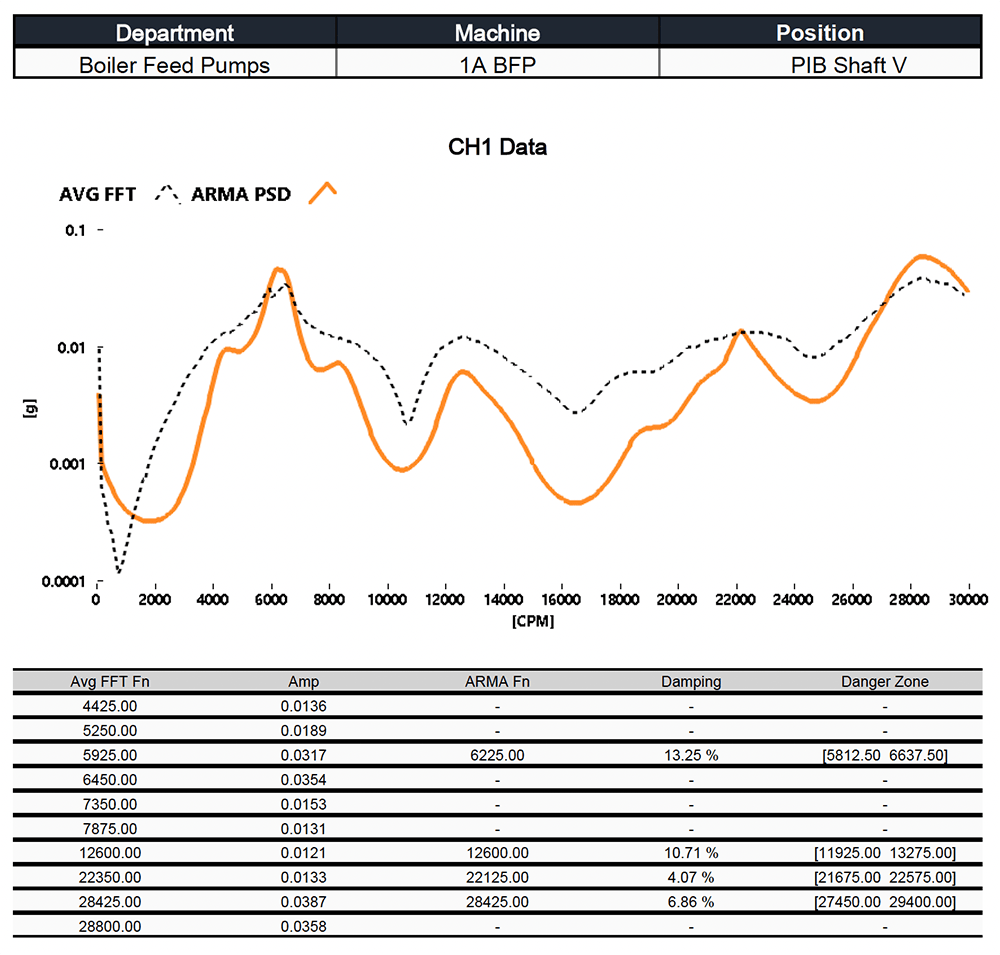

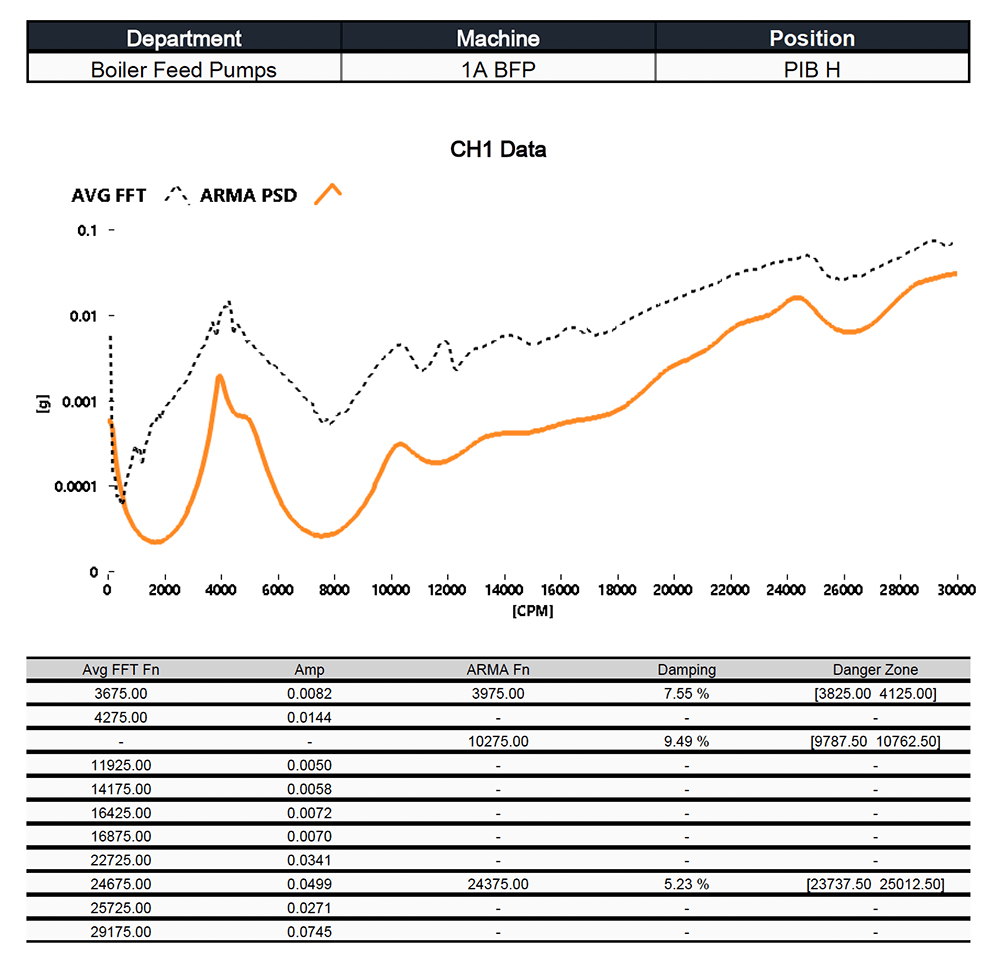

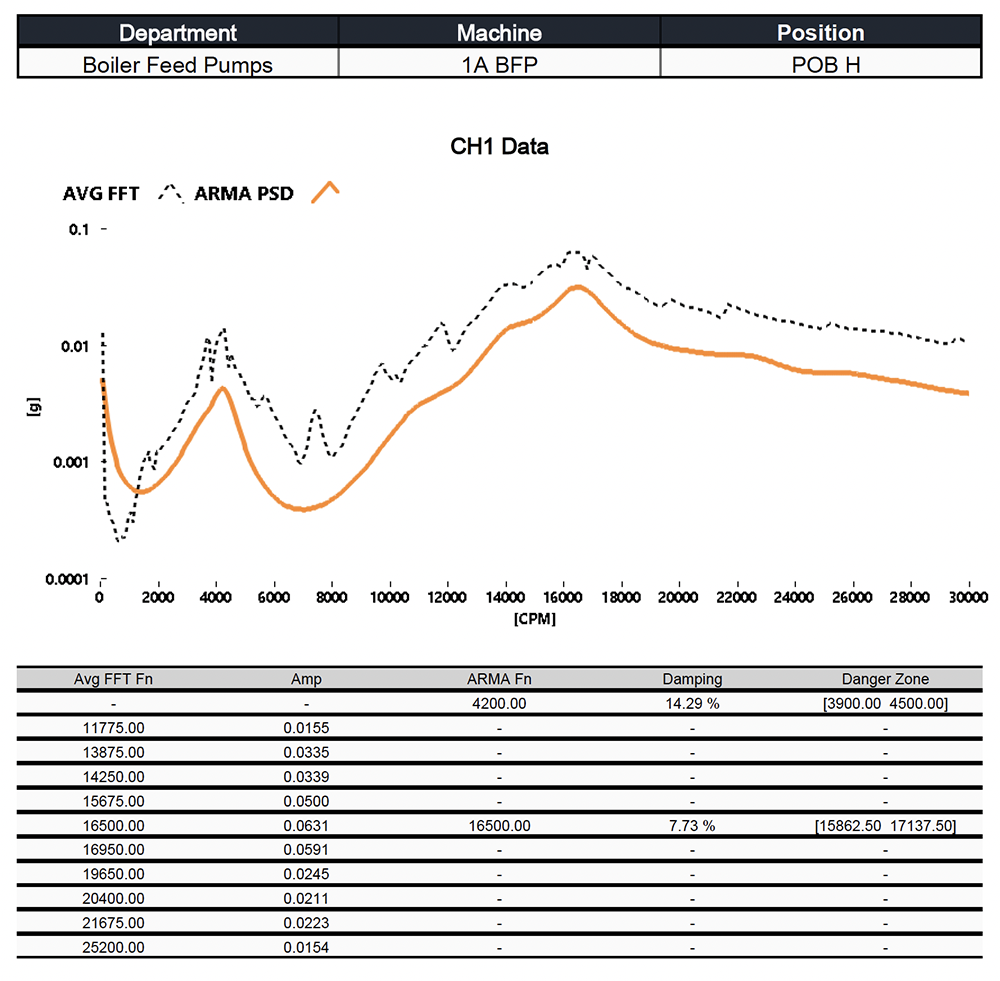

Impact Test Report 1

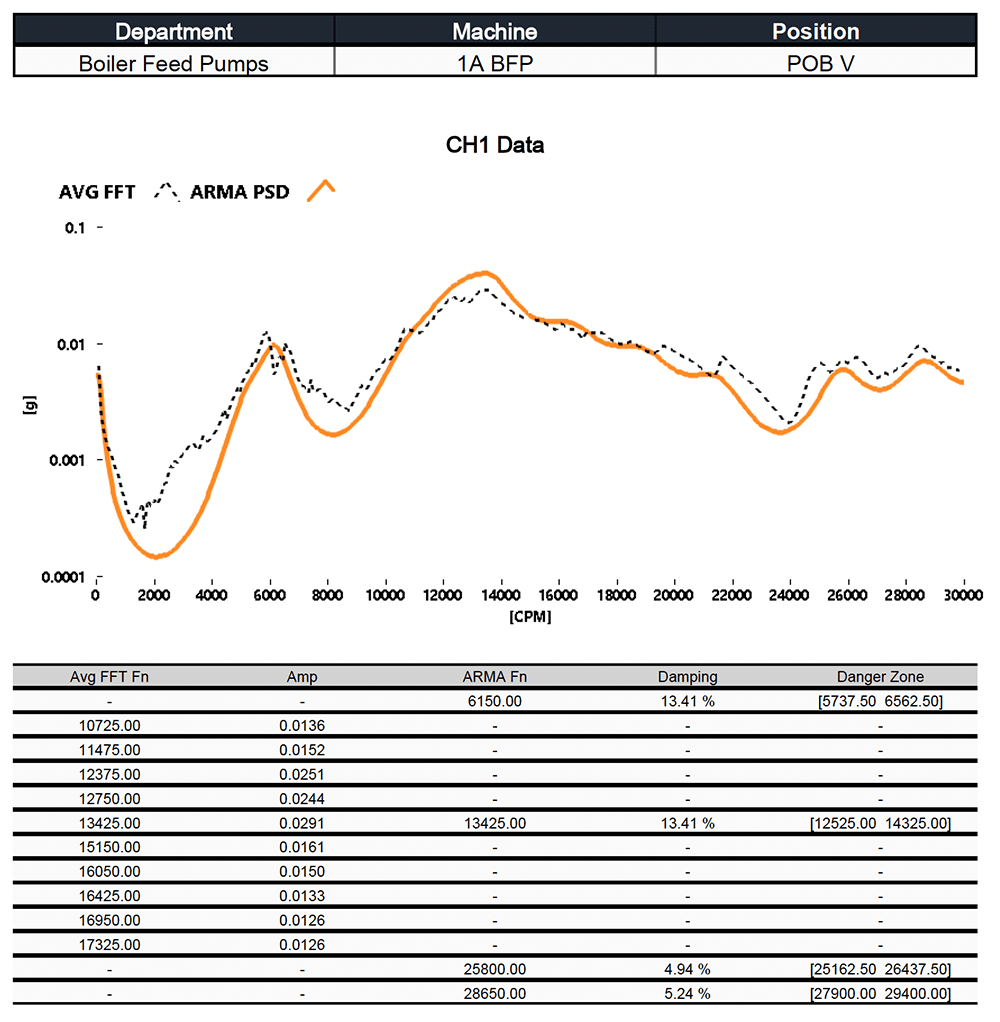

Impact Test Report 2

Impact Test Report 3

Impact Test Report 4

Impact Test Report 5

Impact Test Report 6