Dual Vibration & Temperature Analysis in Condition Monitoring Sensors

Monitoring both vibration and temperature is crucial in condition monitoring for several reasons. Combining these two parameters provides a more comprehensive view of the health and performance of machinery, allowing for early detection of potential issues and proactive maintenance. Here are key reasons why monitoring both vibration and temperature is important in condition monitoring:

Early Fault Detection

Vibration monitoring is effective in detecting mechanical issues such as misalignment, imbalance, and bearing faults. Temperature monitoring, on the other hand, can reveal anomalies related to overheating, electrical problems, or issues with lubrication. By monitoring both parameters, maintenance teams can detect a broader range of potential faults at an early stage.

Identification of Root Causes

When abnormalities are detected, monitoring both vibration and temperatures helps in identifying the root causes of the issues. For example, elevated temperature could indicate an electrical problem that is affecting the mechanical components, and vibration patterns can further pinpoint the specific mechanical fault.

Preventive Maintenance Planning

By monitoring both parameters, maintenance teams can plan preventive maintenance more effectively. Temperature trends may indicate gradual degradation or wear, while changes in vibration patterns may suggest imminent mechanical failures. Combining these insights allows for proactive maintenance, preventing unplanned downtime, and reducing the risk of catastrophic failures.

In summary, monitoring both vibration and temperature in condition monitoring provides a holistic and proactive approach to equipment health. CTC offers a wide range of dual output temperature and vibration sensors that are easily implemented into any condition monitoring program:

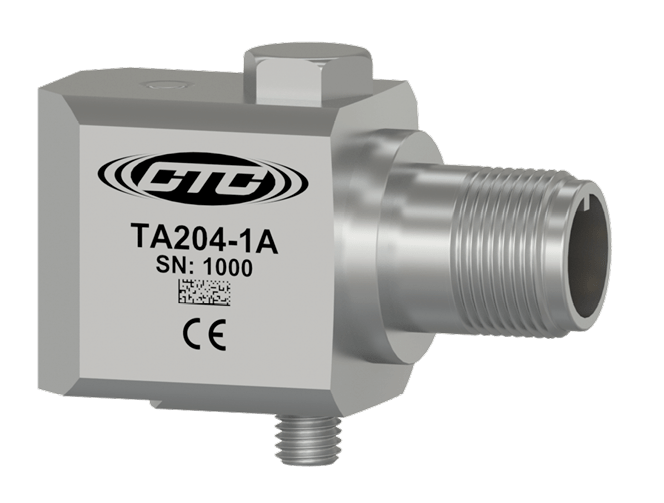

CTC's TA Series Dual Output Acceleration and Temperature Sensors are some of CTC's most popular sensors. They are intended for permanent mount applications and provide both temperature (10 mV/°C) and acceleration (10, 50, 100, or 500 mV/g) outputs in one sensor via a standard 3 Pin MIL connection. As aresult, they are a great tool for monitoring bearing defects and temperature changes in a wide variety of industrial applications.

TA202

Dual output temperature & acceleration sensor, top exit, 100 mV/g, 10 mV/°C, ±10% sensitivity tolerance

TA204

Dual output temperature & acceleration sensor, side exit, 100 mV/g, 10 mV/°C, ±10% sensitivity tolerance