Vibration Monitoring for the Cement Industry

Download the printer-friendly Vibration Monitoring for the Cement Industry Application Note

CTC recognizes that the equipment used within a cement plant is subject to heavy use, dirty environments, and often high temperatures. These factors can result in increased wear and tear on rotating components, creating the threat of premature failure. Condition monitoring programs can be used to monitor the vibration of the bearings throughout the plant and improve the reliability of the overall process.

Common Applications

Important equipment, including crushers, mills, precipitators, kilns, and silos, rely heavily on motors, pumps, and fans, which have rotating components that can be monitored.

What We Offer

CTC offers a variety of accelerometers, mounting hardware, cables, and connectors for cement industry applications. CTC products can be used to craft the perfect vibration monitoring solution for important rotating machinery to ensure operational uptime, increase the efficacy of predictive maintenance, and maintain reliability and safety standards.

Process Monitoring

4-20 mA loop power sensors will provide the overall vibration level of the machine so that it can be trended and alarmed using the plant DCS, PLC, or SCADA system. Process monitoring will require permanently mounted loop power sensors like LP202, LP204, LP302, or LP304 series that output a 4-20 mA signal proportional to velocity or acceleration.

LP202 Loop Power Sensor

4-20 mA Output Proportional to Vibration in Velocity, Top Exit 2 Pin Connector

LP204 Loop Power Sensor

4-20 mA Output Proportional to Vibration in Velocity, Side Exit 2 Pin Connector

LP302 Loop Power Sensor

4-20 mA Output Proportional to Vibration in Acceleration, Top Exit 2 Pin Connector

LP304 Loop Power Sensor

4-20 mA Output Proportional to Vibration in Acceleration, Side Exit 2 Pin Connector

Dynamic Vibration Analysis

The use of CTC accelerometers or Piezo Velocity Sensors can provide detailed information on the frequency and amplitude of vibrations generated by the machine. Dynamic vibration analysis can be in the form of portable or permanent measurements. Portable vibration analysis requires a data collector, accelerometer, mounting magnet, and data collector cable with a break-away safety feature. Online (permanent) vibration monitoring requires permanently mounted accelerometers, durable cabling, and an appropriate connector. Suggested products for online monitoring include AC192, AC194, UEB332, or TREA330 permanently-mounted accelerometers.

AC192 Compact Size Accelerometer

Multipurpose Accelerometer, Top Exit 2 Pin Connector, 100 mV/g, ±10% Sensitivity Tolerance

AC194 Compact Size Accelerometer

Multipurpose Accelerometer, Side Exit 2 Pin Connector, 100 mV/g, ±10% Sensitivity Tolerance

UEB332 Dynamic Vibration IEPE Ultrasound Sensor

1/4-28 Mounting, Top Exit 2 Pin Mini-MIL Connector, 100 mV/g, ±10% Sensitivity Tolerance

UEA332 Dynamic Vibration IEPE Ultrasound Sensor

1/4-28 Mounting, Side Exit 2 Pin Mini-MIL Connector, 100 mV/g, ±10% Sensitivity Tolerance

TREA330 Premium Miniature Triaxial Accelerometer

Side Exit 4 Pin Mini-MIL Connector, Follows Cartesian Phase Coordinate System, 100 mV/g, ±5% Sensitivity Tolerance

Suggested Accessories for Process Monitoring & Dynamic Vibration Analysis

Durable cabling such as CB111, CB206, CB606, or CB602 combined with the V2N (for CB111 only) or A2N connectors over-molded on the cables can be used with loop power sensors or standard CTC accelerometers to provide reliable connectivity back to the vibration monitoring system. CTC’s nylon connectors are the ideal choice for use with multi-purpose accelerometers and Dual Output Sensors. Our nylon connectors have strong chemical resistance for caustic environments to protect the efficacy of your data. For high moisture concerns, select V Series Viton™ seal-tight boots for an IP69-rated seal.

V2N Standard Accelerometer Compatible Connector

2 Socket MIL-Style, Seal-Tight Viton™ Boot Connector with Nylon Insert, Permanent Mount, 250 °F (121 °C) Max Temp

A2N Biaxial and Dual Output Accelerometer Compatible Connector

2 Socket MIL-Style, Nylon Molded Connector, Permanent Mount, 250 °F (121 °C) Max Temp

Combined Approach

A combination of process monitoring and dynamic vibration analysis will create a full coverage approach to provide operations and vibration analysts with the necessary tools to maintain daily production quotas. A combined approach will require accelerometers to measure the dynamic vibration, or piezo velocity sensors for low-frequency vibration (velocity < 10 Hz), and a four-wire transmitter (SC300 series) to convert the dynamic signal to 4-20 mA output for trending and alarming on the DCS, PLC, or SCADA systems. In this application, if the control room notes a change in the amplitude of the vibration via the 4-20 mA signal, the analyst can use the dynamic output of the transmitter to identify the frequency fault and determine what is wrong with the machine.

Dual Output Offerings

CTC also offers dual output sensors, which combine temperature and vibration measurements into a single sensor for the permanent and reliable assessment of the overall condition of the machine. CTC Dual Output Sensors like the TA202, TA204, TA231, TA284, TA233, and TA234 can provide dynamic vibration and temperature inputs to the SC300 series signal conditioner. The signal conditioner will then transmit the overall vibration and temperature as 4-20 mA signals to the DCS, PLC, or SCADA systems.

TA202 IEPE Dual Output Sensor

Temperature and Acceleration, Top Exit 3 Pin Connector, 100 mV/g, 10 mV/°C, ±10% Sensitivity Tolerance

TA204 IEPE Dual Output Sensor

Dual Output Sensor, Temperature and Acceleration, Side Exit 3 Pin Connector, 100 mV/g, 10 mV/°C, ±10% Sensitivity Tolerance

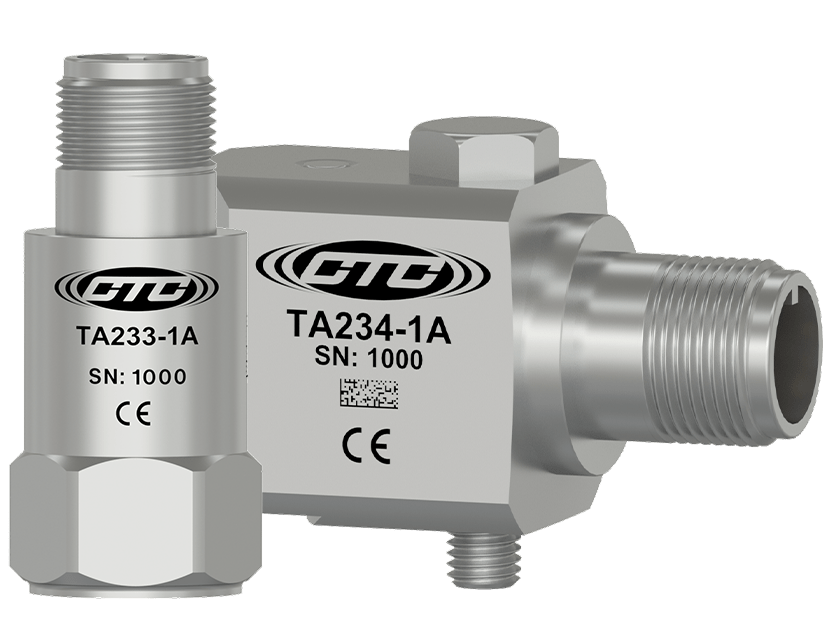

TA233 IEPE Dual Output Sensor

Temperature and Acceleration, Top Exit 3 Pin Connector, 500 mV/g, 10 mV/°C, ±10% Sensitivity Tolerance

TA234 IEPE Dual Output Sensor

Temperature and Acceleration, Side Exit 3 Pin Connector, 500 mV/g, 10 mV/°C, ±10% Sensitivity Tolerance

TA284 IEPE Dual Output Sensor

Temperature and Acceleration, M8x1.25 Captive Bolt, Side Exit 3 Pin Connector, 100 mV/g, 10 mV/°C, ±10% Sensitivity Tolerance

Recommended Enclosures

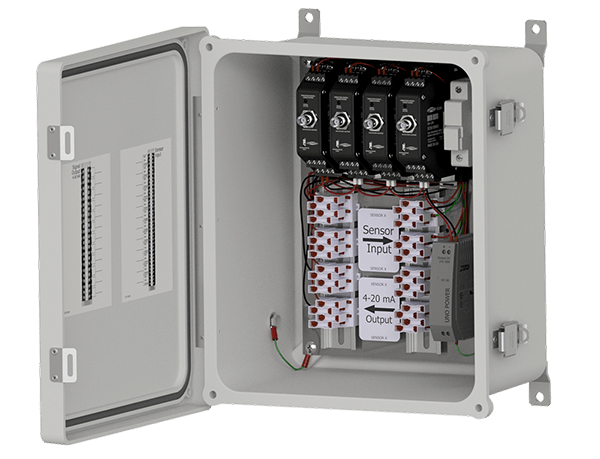

SCE Series: Dynamic Output for Analysis

- Input options: 1-4 or 1-8 CTC Signal Conditioners

- Provides 4-20 mA signals along with dynamic outputs

- Fiberglass and stainless steel options available

- NEMA 4X (IP66) rated

- 15 to 140 °F (-10 to 60 °C) temperature range

- Includes DC power supply with 100-240 VAC input

PMX Series Vibration Relay and Display System

- Input options: 1-4 single output loop power sensors

- trigger alarms and shutdown machinery

- Sunlight-viewable display of vibration levels, IPS, g's, Mils, or customized scale

- Fiberglass enclosure

- NEMA 4X (IP66) rated

- 32 to 140 °F (0 to 60 °C) temperature range

- Includes DC power supply with 100-240 VAC input

SCD100 Series Vibration Relay and Display System

- Input options: 1-4 CTC signal conditioners

- Trigger alarms and *shut down machinery

(*available only when used without stack light) - Sunlight-viewable display of vibration levels, IPS, g's, Mils, or customized scale

- Optional red stack light and horn alarm available

- Fiberglass enclosure

- NEMA 4X (IP65 rated)

- 32 to 140 °F (0 to 60 °C) temperature range

- Includes DC power supply with 100-240 VAC input

- Input options: 4-12 or 24-48 single output, dual output, or triaxial output sensors

- Convenient fold-forward interface panel for easy wiring

- IEPE sensor condition indication lights on front panel

- Fiberglass, stainless steel, or sloped top stainless steel options available

- Internally earth grounded for noise reduction

- NEMA 4X (IP66) rated

- -58 to 18 °F (-50 to 82 °C) temperature range

MX Series: Enclosed BNC Connection Boxes

- Input options: 1-4 or 1-12 single output sensors and 1-2 dual output sensors

- Convert output of permanently-mounted accelerometer or piezo velocity sensors to BNC output

- Terminal strip behind BNC panel for easy wiring

- Fiberglass, polycarbonate, or powder-coated aluminum options available

- Internally earth grounded for noise reduction

- NEMA 4X (IP66) rated

- -58 to 180 °F (-50 to 82 °C) temperature range