Vibration Monitoring for the Steel Industry

Download the printer-friendly Vibration Monitoring for the Steel Industry Application Note

A steel mill undergoes some of the harshest conditions when creating and processing steel. The machines are put through brutal conditions, including hot temperatures, dangerous chemicals and toxins, and heavy usage. As a result, vibration monitoring is critical to ensure operational uptime, human safety, product efficacy, and machine longevity.

Common machinery found within steel mills includes:

- Blast furnaces

- Rolling mills

- Quench boxes

- CCM (Continuous Casting Machine)

- Straightening machines

- Loopers

- Girders

- Conveyors

- Motors

- Heaters

- Boilers

- Pumps

- Pipelines

- Cranes

Common failures within steel mills include:

- Improper lubrication of machinery

- Roll bearing failures

- Hydraulic pump failures

There are several challenges of monitoring within a steel mill, including:

- Hot temperatures

- Safety concerns

- Toxic chemicals and gases

- Limited accessibility

- What needs to be continuously monitored?

- Selecting the proper equipment for harsh environments

Due to the diversity of processes in steel manufacturing, CTC recommends tailoring your vibration monitoring hardware to the specific process and environment. Permanent monitoring is the preferred method for a lot of these processes, both for repeatability as well as human safety concerns for hard-to-reach places and hot, caustic environments.

The first consideration is whether or not process monitoring or dynamic vibration analysis is right for your condition monitoring program:

Process monitoring requires 4-20 mA loop power sensors, which will provide the overall vibration level of the machine so that it can be trended and alarmed using the plant DCS, PLC, or SCADA system. Process monitoring will require permanently mounted loop power sensors that output a 4-20 mA signal proportional to velocity or acceleration. Process monitoring will provide an overall understanding of machine health, but cannot provide the same level of detailed, diagnostic data as dynamic vibration analysis.

Dynamic vibration analysis allows for trended data and machine health diagnostics. However, dynamic vibration sensors can be paired with CTC’s SC300 Series signal conditioners to create a hybrid approach for both process monitoring and dynamic analysis. A signal conditioner converts the signal from a dynamic sensor into a 4-20 mA output, so it can be trended and alarmed using the plant DCS, PLC, or SCADA system but also used for more in-depth predictive maintenance.

Regardless of whether or not a signal conditioner is the right choice for your program, CTC has a variety of accelerometers for use in steel industry applications.

Standard Accelerometer Offerings (for environments up to 250 °F):

AC102 & AC104 Multipurpose Accelerometer, Top or Side Exit 2 Pin Connector, 100 mV/g, ±10%, ±80 g, Dynamic Range

AC292 & AC294 Premium Compact Accelerometer, Top or Side Exit 2 Pin Connector, 100 mV/g, ±5%, ±80 g, Dynamic Range

UEB332 & UEA332 Dynamic Vibration IEPE Ultrasound Sensor, Top or Side Exit 2 Pin mini-MIL Connector, 1/4-28 Mounting, 100 mV/g, ±10%, ±50 g, Peak

AC133 & AC134 Low-Frequency Accelerometer, 2 Pin Connector, 500 mV/g, ±10%, ±50 g, Peak

High-Temperature IEPE Offerings (for environments up to 325 °F):

AC207 & AC208 High-Temperature Accelerometer, Top or Side Exit 2 Pin Connector, 100 mV/g, ±10%

TXEA331-HT High-Temperature Triaxial Accelerometer, Side Exit 4 Pin Mini-MIL Connector, 100 mV/g, ±5%

Dual Output Vibration & Temperature Offerings:

TA202 & TA204 Dual Output Sensors, Temperature & Acceleration, Top or Side Exit 3 Pin Connector, 100 mV/g, 10 mV/°C, ±10%

TR102-M12A & TR104-M12A RTD Sensors, Temperature & Acceleration, Top or Side Exit 4 Pin M12 Connector, 100 mV/g, ±10%

VT202 & VT204 Dual Output Piezo Velocity Sensors, Velocity & Temperature, Top or Side Exit 3 Pin Connector, 100 mV/in/sec, 10 mV/°C, ±10%

Signal Conditioners & Enclosures:

SC300 Series USB-configurable signal conditioners are offered in single-band vibration or dual-band vibration output options

All SC300 Series signal conditioners come equipped with an optional temperature output, which can be utilized with CTC TA200 Series dual output vibration and temperature sensors.

SCE210 Series NEMA 4X, stainless steel enclosure for up to eight SC Series signal conditioners

SCD100 NEMA 4X, fiberglass vibration relay & display enclosure for up to four SC Series signal conditioners, with the option to include switch relay or display only, and optional red stack light

Recommended Cabling & Connector Offerings:

For the steel industry, CTC recommends choosing rugged cabling and connectors for optimal chemical compatibility and heat resistance.

Our Viton™ Boot Series (V Series) Connectors are available in both single-axis, dual-output, and triaxial compatible options. V Series Connectors offer the best chemical resistance, an IP69 connection, and high heat resistance.

Our A Series Connectors are also a great option for steel industry applications, with a variety of material options. CTC recommends PPS or Nylon A Series Connectors for chemical resistance purposes.

A2R & A3R PPS Molded Standard MIL Connector, 392 °F (200 °C) Maximum Temperature

A2Y & A3Y Nylon Molded Right Angle Connector, 250 °F (121 °C) Maximum Temperature

V2N & V3N Molded Viton™ Seal-Tight Boot Connector with Nylon Insert, 250 °F (121 °C) Maximum Temperature

V2R & V3R Molded Viton™ Seal-Tight Boot Connector with PPS Insert, 350 °F (177 °C) Maximum Temperature

CB111 Yellow FEP Jacketed Cable, 0.19 in. (4.8 mm) OD, 392 °F (200 °C) Maximum Temperature

CB206 Stainless Steel Armor Jacketed Cable, 0.27 in. (6.9 mm) OD, 392 °F (200 °C) Maximum Temperature

CB602 Stainless Steel Armor Jacketed Cable, 0.27 in. (6.9 mm) OD, 392 °F (200 °C) Maximum Temperature

CB502 FEP Jacket with Hydraulic Hose Outer Armor, 0.5 in. (12.7 mm) OD, 212 °F (100 °C) Maximum Temperature

Junction Box Offerings:

Junction Boxes can be used for local measurements or the transmission of data to online vibration monitoring systems. Junction Boxes can also be used for cable reduction purposes or for switched outputs during manual route data collection of the vibration signals. Due to the harsh environments present in steel manufacturing, stainless steel Junction Boxes are recommended.

Compare some of our most popular junction box enclosures below:

| JB200 Series | SB200 Series | MX200 & MX300 Series | CR202 Series |

|

|

|

|

|

Premium Switch Box with IEPE bias indicator light and convenient flip-down panel for wiring |

Legacy Switch Box Series |

Enclosed BNC Connection Boxes |

Cable Reduction Box for consolidating cables and reducing costs |

|

Available in single-axis, dual input & output, and triaxial input & output configurations |

Available in single-axis and dual input & output configurations |

Available in single-axis, dual input & output, and triaxial input & output configurations |

Single-axis sensor inputs |

|

Minimum channel count: 4 sensor inputs Maximum channel count: |

Minimum channel count: Maximum channel count: |

Minimum channel count: 1 sensor input Maximum channel count: |

Minimum channel count: Maximum channel count: |

Loop Power Sensor Offerings for Process Monitoring:

LP202 & LP204 4-20 mA Output Proportional to Vibration in Velocity

LP302 & LP304 4-20 mA Output Proportional to Vibration in Acceleration

Relay & Display Equipment for Use with Loop Power Sensors:

PMX Series Fiberglass, 1-4 channel process control enclosure with display and relay, with optional red or tri-color stack light

These enclosures are designed for loop power sensor input, and the relays can trigger alarm or shutdown.

Predictive Maintenance for Fluid Film Bearings:

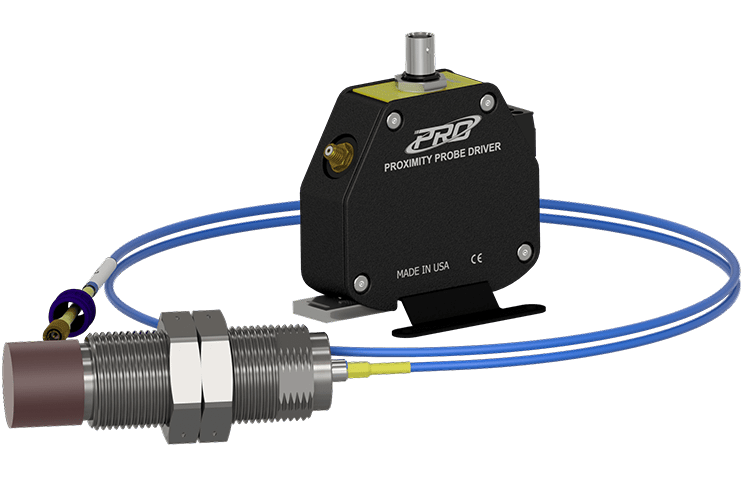

Many large motors, generators, and gearboxes will incorporate fluid film bearings to support their rotating shafts. These shafts require monitoring, which can be done through the use of X and Y radial proximity probes.

CTC’s PRO Line Proximity Probes are non-contact eddy current sensors that measure the vibration of the shaft relative to the case of the machine, and the location (gap) of the shaft in the bearing. CTC offers FFv™ 5 mm, 8 mm, 11 mm, and 25 mm probes in both standard and armor-jacketed cables. Compatible drivers and extension cables are available for all systems.

FFv™ 5 mm Proximity Probe Set

8 mm Proximity Probe Set

11 mm Proximity Probe Set

25 mm Proximity Probe Set

CTC offers a wide variety of driver output options as well as driver calibration materials, including:

- 4140 Steel

- 1045 Carbon Steel

- 17-4 Stainless Steel

- 420 Stainless Steel

- 304 Stainless Steel

- 316L Stainless Steel

- 360 Brass Alloy

- AL7075-T6 Aluminum

- 200 Nickel

- 410 Stainless Steel