SUCCESS STORIES & CASE STUDIES

Learn about how our customers use CTC condition monitoring products in the field for the most reliable and repeatable data acquisition.

Success Story Snapshots

Seeing is believing! Check out real-life examples of customers’ successful CTC vibration analysis hardware installations across a wide range of machinery and applications.

A CTC TREA330 triaxial accelerometer mounted on a pump

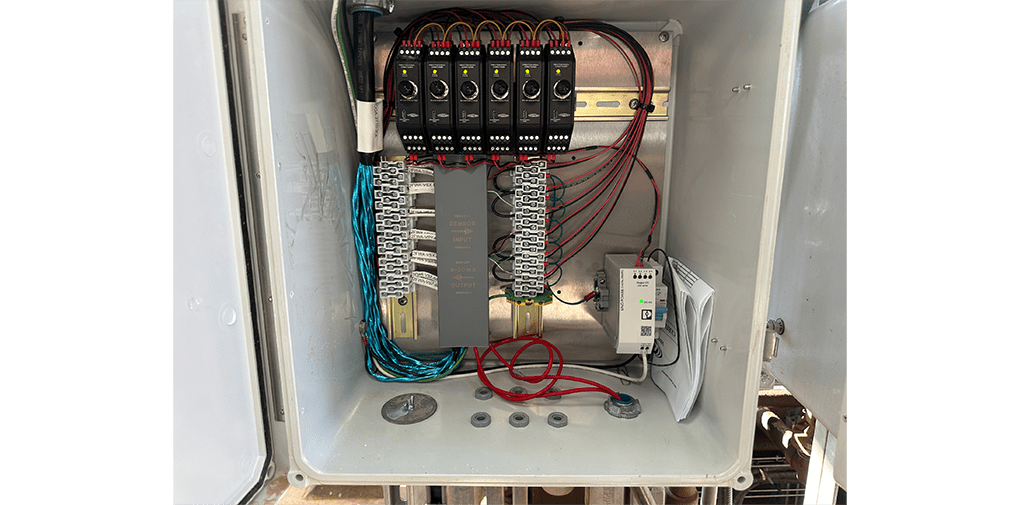

The interior of a SCE310 Series fiberglass signal conditioner enclosure shown with 6 installed CTC Signal Conditioners wired to a power source

Three mounted SCE Series fiberglass signal conditioner enclosures used for monitoring pumps

A magnet-mounted TREA330 Series triaxial accelerometer on a pump

CTC triaxial sensor with cable and connector cordset hooked up to a data collector

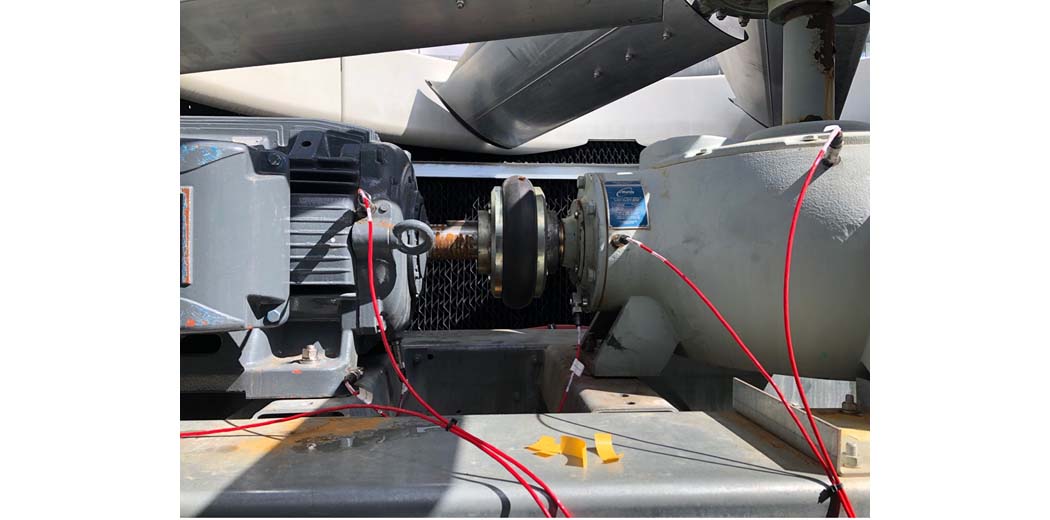

CTC triaxial sensor mounted on an industrial motor

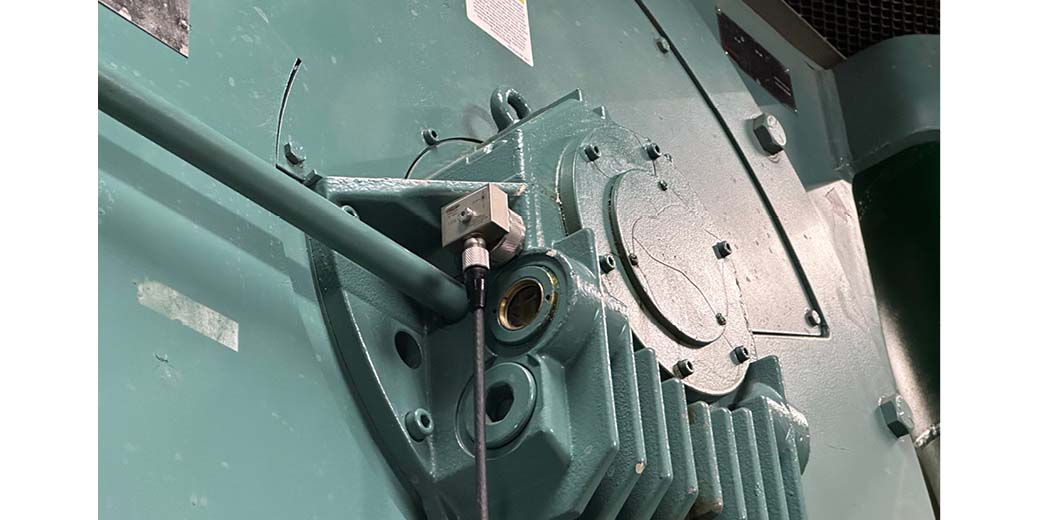

CTC side exit accelerometers permanently mounted and connected to armor jacketed cabling

A mounted TREA331 triaxial accelerometer, cable, and connector

An AC102 Accelerometer and boot connector

A permanently mounted magnetic vibration test point

The interior of a JB130 fiberglass iBox enclosure

The interior of an MX704 Mini-MAXX Enclosure

An MX704 Mini-MAXX fiberglass Enclosure shown with cover closed

JB130 iBox Enclosure's convenient fold-out panel

A VibeNavigator Extension Pole used to take a reading on a hard-to-reach motor

A TSB1000 Series fiberglass enclosure for triaxial input and output

A UEB332 Ultrasound Sensor mounted on an Vibration Test Point

Single axis, top exit accelerometers with CB102 cabling

A closeup of a TREA330 Triaxial Accelerometer on a flat surface mounting magnet

A closeup of a permanent mounted side exit, single axis AC144-1D accelerometer

A CTC top exit accelerometer and cable assembly mounted on a chiller unit

A closeup of TREA331 Triaxial Accelerometer mounted on a chiller

Two TREA331 Triaxial Accelerometers mounted on an industrial chiller

A TREA331 Triaxial Accelerometer mounted using a curved surface magnet

A closeup of a mounted mini size AC244 single axis, side exit accelerometer

A closeup of a mounted AC102-1A standard size top exit accelerometer

Two CTC sensors and cable assemblies mounted on a vertical pump

An installed SSB1000 fiberglass vibration switch box for single axis accelerometers

A closeup of a AC115 triaxial accelerometer mounted inside of a water treatment plant

A UEA334 side exit ultrasound sensor with breakaway safety feature cordset

Triaxial accelerometers mounted on water pump motors

A TREA330 triaxial accelerometer and cable assembly

A vibration analysts takes a reading from a CTC accelerometer mounted on a motor

A mounted triaxial sensor connected to a data collector via a CTC cable and connector cordset

A magnet mounted top exit accelerometer connected to a data collector

Two wall-mounted fiberglass MAXX Box enclosures

A fiberglass MX102 MAXX box enclosure with four channels wired

Three magnet mounted single-axis, top exit accelerometers on a motor

A close up of three magnet-mounted single-axis top exit sensors

Three magnet-mounted single-axis top exit accelerometers

Magnet-mounted standard size, top exit, single-axis accelerometers

A magnet mounted top exit sensor connected to a data collector

A compact size AC192 top exit accelerometer magnet-mounted on a motor

A magnet-mounted TREA330 Series Triaxial Accelerometer

Close up of data readings on a data collector taken from a mounted triaxial accelerometer

A closeup of a magnet-mounted TREA330 Series triaxial accelerometer and connector

A TREA Series triaxial accelerometer connected to a data collector via finger-cable cordset

A TREA330 triaxial accelerometer magnet-mounted on a pump

Two mounted, side-exit accelerometers and cordsets with armored jacketed cabling.

A closeup of an MEB360 Series Molded Accelerometer with integrated rotating locking nut

Magnet-mounted triaxial and top exit, single-axis accelerometers on the same machine

A TREA330 triaxial accelerometer on a curved surface mounting magnet

A data collector taking readings from a top exit and side exit single axis accelerometer

A TSB1000 Series fiberglass switch box

The interior of a TSB1000 Series Switch Box

Single axis, top exit accelerometers with integral cable connectors

The interior of an SB102 Series fiberglass switch box

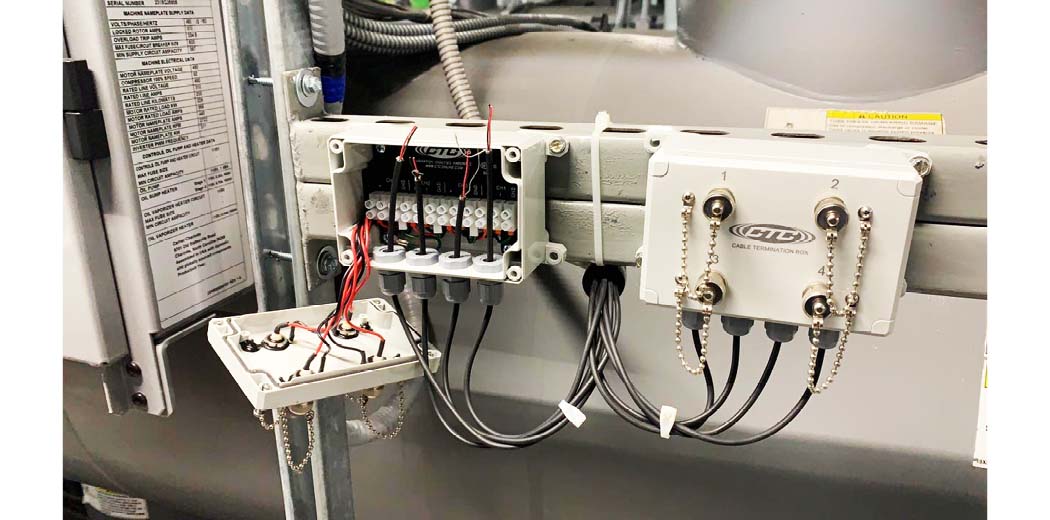

Two cable termination boxes, shown open and closed

A technician wiring a cable termination box

An analyst uses a data collector to take readings from a TCEB330 Series circular triaxial accelerometer

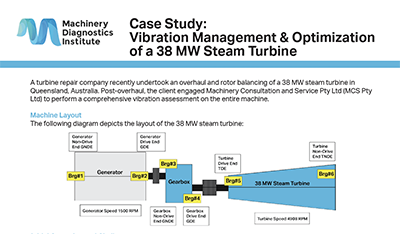

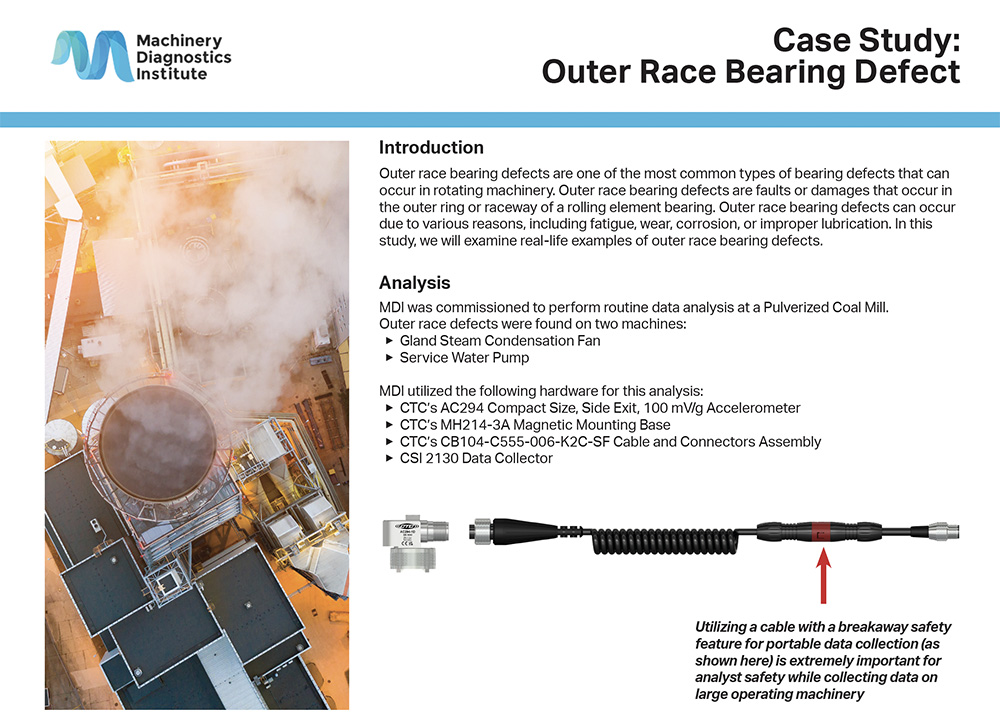

Case Studies

Find out how CTC customers create the perfect condition monitoring solutions using our innovative and rugged vibration monitoring hardware. See what hardware is used together for superior results for a wide variety of specific monitoring applications and environments, and examine the data obtained during these predictive maintenance programs. You'll gain valuable insight into methods for spotting and preventing potential faults, from experts in the industry.